Views: 1000 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

Complete Solution for 3/5/10ml Syringe Production Line

In today’s medical and pharmaceutical industries, ensuring the production of high-quality, reliable syringes is essential. A complete solution for 3ml, 5ml, and 10ml syringe production lines encompasses everything from mold design to packaging, offering manufacturers an efficient, high-speed, and high-quality production process.

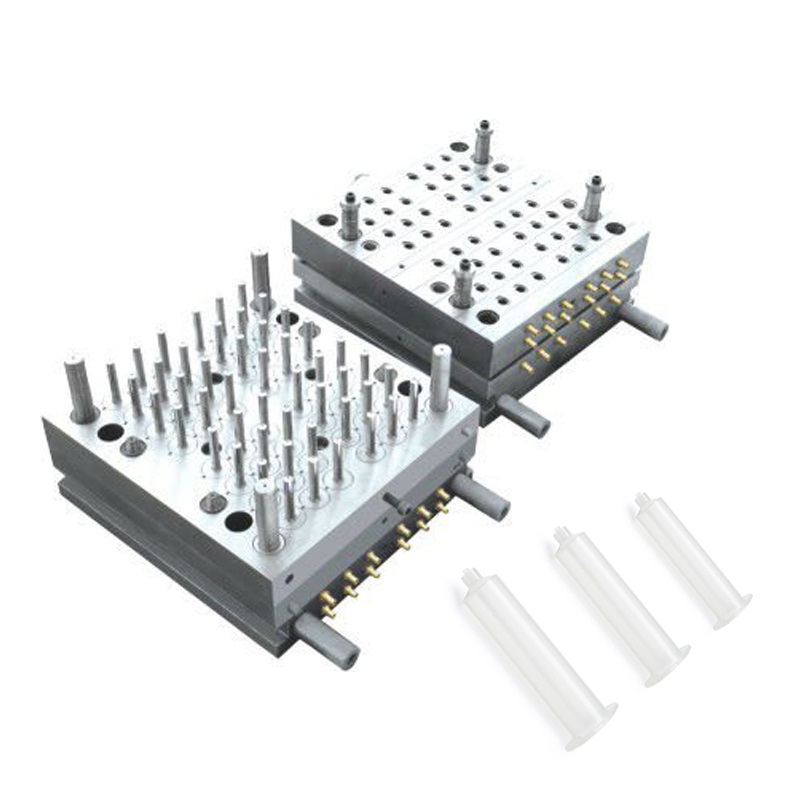

The backbone of any syringe production line is its mold system. The production of syringes begins with the creation of the barrel mold, plunger mold, and gasket mold. These molds are custom-designed to meet specific production requirements and ensure the precise formation of each syringe component.

Barrel Mold: This mold forms the main body of the syringe, which holds the medication.

Plunger Mold: This mold shapes the plunger, which is responsible for pushing the fluid within the syringe.

Gasket Mold: The gasket seals the plunger to prevent leakage. (Note: Rubber gaskets are often purchased as ready-made products from external suppliers.)

The number of cavities in each mold can be customized to meet the production capacity requirements of the client. For example, a higher number of cavities can significantly increase output, which is crucial for large-scale production. A custom cavity design ensures that the production line is optimized for both speed and cost-efficiency.

Each mold requires a matching injection molding machine to produce the syringe components. Typically, one mold is matched with one injection molding machine, ensuring high precision and the consistency of each part. The machine injects plastic or other materials into the mold to create the barrel, plunger, and gasket components.

The injection molding machine must be carefully selected based on the mold's size, material requirements, and the desired production speed. The precision of the injection molding process directly impacts the quality of the syringe parts, which is why the compatibility between the mold and the injection molding machine is critical.

Once the syringe barrels are formed, they need to be marked with a scale line to indicate volume levels. This is where the pad printing machine plays an essential role. It prints precise scale lines onto the barrel of the syringe, a key feature for ensuring accurate medication dosage.

The pad printing machine uses oil-based ink that adheres well to the syringe barrel, ensuring that the printed scale lines are clear, legible, and resistant to peeling. The printing process is critical to ensure that the final product meets medical standards, as any unclear or inaccurate scale lines can lead to errors in medication dosage.

The capacity of the pad printing machine ranges from 220-250 syringes per minute, or approximately 13,200-15,000 syringes per hour, making it suitable for high-volume production lines.

After the syringe components (barrel, plunger, gasket, and needle) are molded and printed, the next step is assembly. The syringe assembly machine is responsible for bringing together all the components with high speed and stability.

The machine’s high-speed assembly ensures that each syringe is correctly assembled with minimal downtime. For 3ml and 5ml syringes, the assembly machine can process 220-250 syringes per minute (13,200-15,000 per hour), while for 10ml syringes, the capacity drops slightly to 180-200 syringes per minute (10,800-12,000 per hour). These high speeds ensure that production lines remain efficient and meet the demands of the market.

Once the syringes are assembled, they need to be securely packed for distribution. The soft blister packing machine is used to pack the syringes with the needle attached, ensuring that each product is sealed and protected during shipping and handling.

For added convenience, some blister packing machines are equipped with an auto loader, which helps reduce labor costs by eliminating the need for 3-4 additional workers. The auto loader automatically feeds syringes into the packing machine, increasing production efficiency and minimizing human error. The HP Ink Jet Coder is integrated into the packing line to print product information, expiration dates, and batch numbers on the packaging paper.

The final step in the syringe production line is sterilization. The ETO (Ethylene Oxide) sterilization machine is used to sterilize syringes and other medical products before they are shipped out. This machine typically includes a sterilizer cabinet, a water tank, and a computer control system that ensures the proper sterilization process is followed. The double-door design allows for safe loading and unloading of syringes without contaminating the sterile environment.

ETO sterilization is essential in the medical industry, as it guarantees that syringes are free from harmful microorganisms and pathogens, making them safe for medical use.

A complete solution for the 3/5/10ml syringe production line integrates a series of highly specialized machines, including injection molding machines, pad printing machines, assembly machines, blister packing machines, and sterilization units, all working in harmony to produce high-quality syringes efficiently. Each machine is crucial to the success of the production line, ensuring that the final product meets the necessary standards for medical use.

By customizing each component of the production line to meet the specific needs and production capacity requirements of the customer, manufacturers can ensure they produce syringes with the highest quality, accuracy, and efficiency. With the right equipment and a carefully designed production process, companies can meet the growing demand for safe, reliable medical syringes while optimizing their production costs.