Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

Efficient and Precise 3-Part Syringe Assembly Machine: Revolutionizing Syringe Production

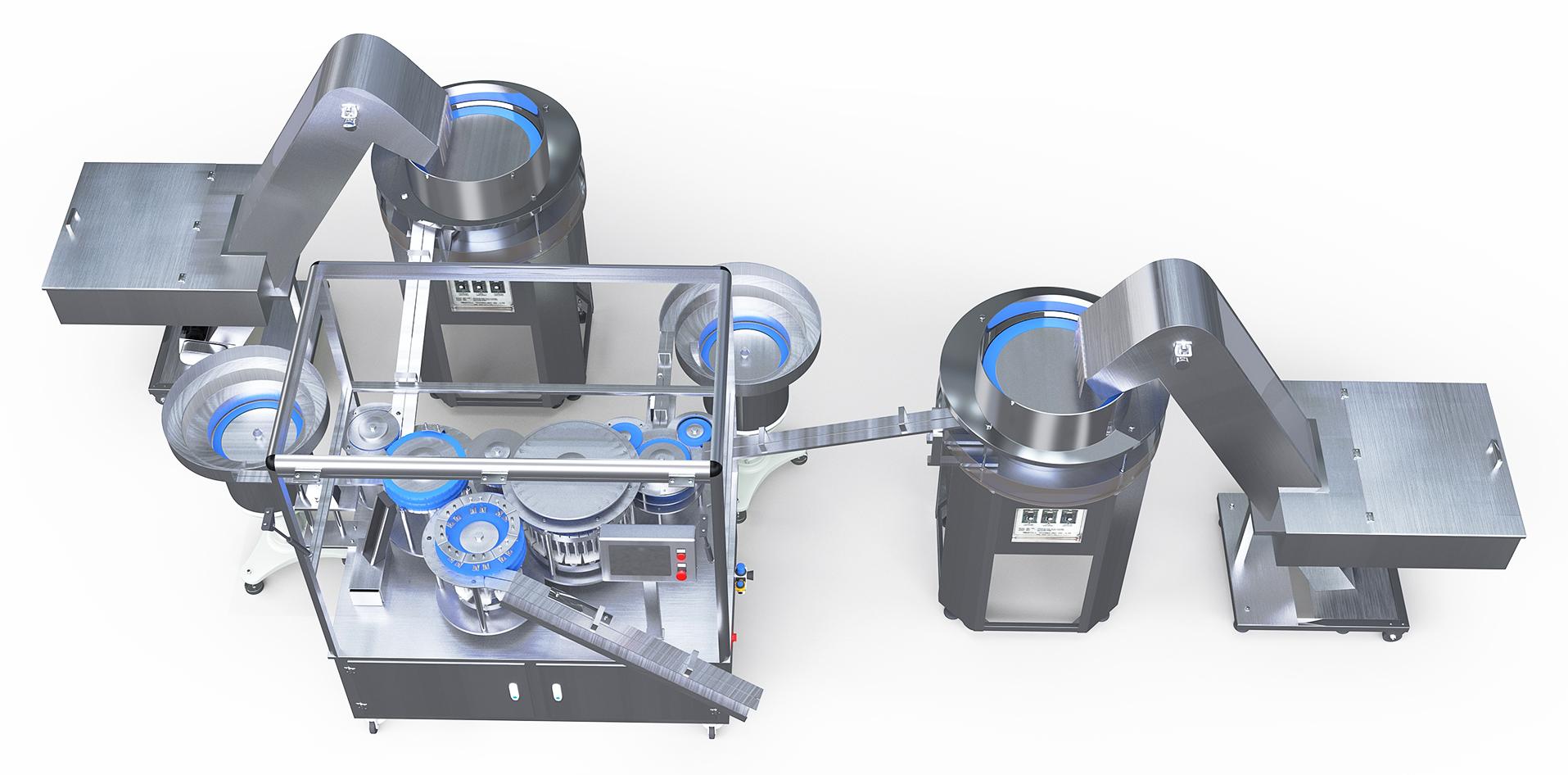

In the medical device industries, the assembly of syringes requires a high degree of precision, efficiency, and speed. The 3-part Syringe Assembly Machine is an advanced solution designed to streamline the assembly of syringes, ensuring high-quality production with minimal downtime. By automating the process of combining the syringe barrel, plunger, and gasket, this kind of machine allows manufacturers to meet the growing demand for medical syringes across different sizes and applications.

One of the standout features of the Syringe Assembly Machine is its flexibility in accommodating syringes of various sizes, from 1ml to 60ml. Each size of syringe requires a dedicated machine to ensure precise assembly and to avoid cross-contamination or improper fitting. The machine’s modular design ensures that it can be easily adapted for different syringe sizes:

1ml, 2ml, 3ml, 5ml, 10ml, 20ml, 30ml, 50ml, and 60ml syringes, with each size requiring a separate assembly machine for optimal performance.

This flexibility ensures that manufacturers can efficiently produce syringes in a wide range of volumes, serving the diverse needs of the healthcare market.

The Syringe Assembly Machine is engineered to assemble all critical parts of the syringe, including the barrel, plunger, and gasket. The precise alignment of these components is vital to ensuring that the syringe functions correctly during medical procedures.

The barrel and plunger are fed into the machine via a centrifuge, which ensures consistent placement and smooth operation throughout the assembly process.

The gasket and hypodermic needle are fed by a vibrating hopper, which allows for precise placement and quick integration into the assembly line.

In addition to assembling the basic syringe components, the machine provides flexibility in how the hypodermic needle is handled. The needle can be either Assembled directly with the barrel on the assembly machine, or Placed beside the syringe during the packaging stage.

This versatility ensures that manufacturers can cater to different packaging requirements and customer preferences, making the machine a highly adaptable solution.

The high-speed Syringe Assembly Machine is built for efficiency, capable of processing large quantities of syringes quickly without compromising quality. The assembly rates vary depending on the syringe size, enabling manufacturers to tailor production speeds to meet specific demands:

For 2-5ml syringes, the machine assembles 220 syringes per minute, 13,200 syringes per hour.

For 1ml and 10ml syringes, the assembly rate is 200 syringes per minute, 12,000 syringes per hour.

For 20-60ml syringes, the machine assembles 180 syringes per minute, totaling 10,080 syringes per hour.

These high-speed capabilities ensure that large volumes of syringes can be produced rapidly, meeting the demands of manufacturers while maintaining high standards of quality.

The machine's design includes efficient feeding systems to ensure smooth operation and minimal risk of assembly errors:

Centrifuge-fed barrels and plungers provide a consistent, reliable method of feeding these components into the assembly line.

Vibrating hoppers ensure that both the gasket and hypodermic needle are fed accurately and in the correct orientation.

These systems significantly reduce manual intervention and prevent assembly line jams, resulting in smoother and faster production cycles.

The Syringe Assembly Machine is built with well-stability to ensure reliable performance over long production runs. This stability is essential for maintaining precise assembly and preventing equipment failure during high-speed operations. Additionally, the machine comes equipped with a protective cover designed to enhance operator safety. The machine automatically stops running when the door is opened, ensuring that operators are not exposed to moving parts while performing maintenance or adjustments. Once the door is closed, the machine restarts automatically, resuming normal operation with minimal delay.

These built-in safety features help reduce the risk of accidents in the production environment and ensure compliance with workplace safety regulations.

The 3-part Syringe Assembly Machine is an indispensable tool for modern syringe production, offering high-speed, precision, and flexibility. With the ability to assemble syringes of various sizes, from 1ml to 60ml, and the option to package hypodermic needles either with or alongside the syringe, the machine adapts to the diverse needs of the medical industry. Its efficient feeding systems, high-speed assembly rates, and safety features make it an essential asset for large-scale manufacturers looking to increase productivity while maintaining strict quality standards.

By investing in the Syringe Assembly Machine, manufacturers can optimize their production lines, meet increasing demand, and deliver high-quality syringes that are safe, reliable, and ready for use in medical applications worldwide.