This syringe making machine is designed for manufacturers who require speed, accuracy, and stability. The equipment includes high-precision molds, automatic assembly systems, and intelligent inspection modules to guarantee product consistency. As part of a complete syringe production line, it ensures smooth coordination from raw material injection to final packaging. The machine supports flexible production of various syringe sizes, making it suitable for new syringe factory set up projects as well as expansion of existing facilities. With low energy consumption and easy maintenance, this syringe production equipment helps reduce operation costs while delivering excellent output.

| Availability: | |

|---|---|

| Quantity: | |

SMT

SMARTELL

Disposable Syringe Production Line

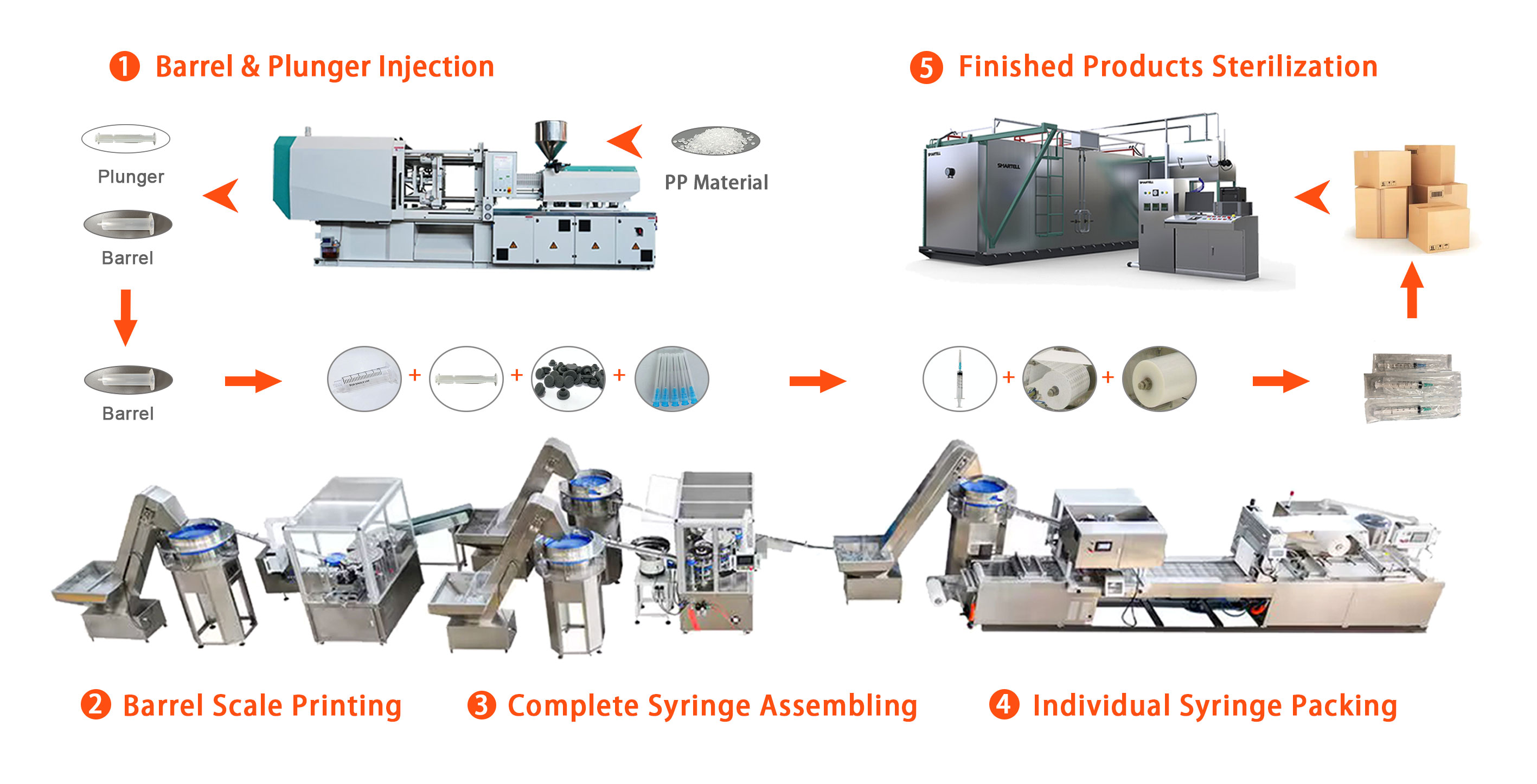

1. Injection Molding

The syringe barrel and plunger are formed by high-precision molds installed on the injection molding machine. Hot-melt PP material is injected into the molds. This is the most critical step, as the mold design and accuracy directly determine the final quality of the syringe.

2. Barrel Printing

Scale lines and logos are printed on the syringe barrel. Clear, durable printing improves both usability and the overall appearance of the syringe.

3. Assembly

All components—barrel, plunger, gasket, and needle—are assembled into a complete syringe. A stable, high-speed assembly machine significantly increases daily production capacity.

4. Packing

Because syringes must remain clean before leaving the clean room, each set requires individual packing. This is done by an automatic blister packing machine or ribbon packing machine, depending on market preference. After individual packing, the syringes are placed into boxes and cartons.

5. Sterilization

To ensure sterility and safety, packed syringes undergo ethylene oxide (ETO) sterilization before entering the market. Optional systems such as preheating units can shorten the sterilization cycle, and residual gas treatment systems can help meet higher environmental standards.

Disposable Syringe Production Line

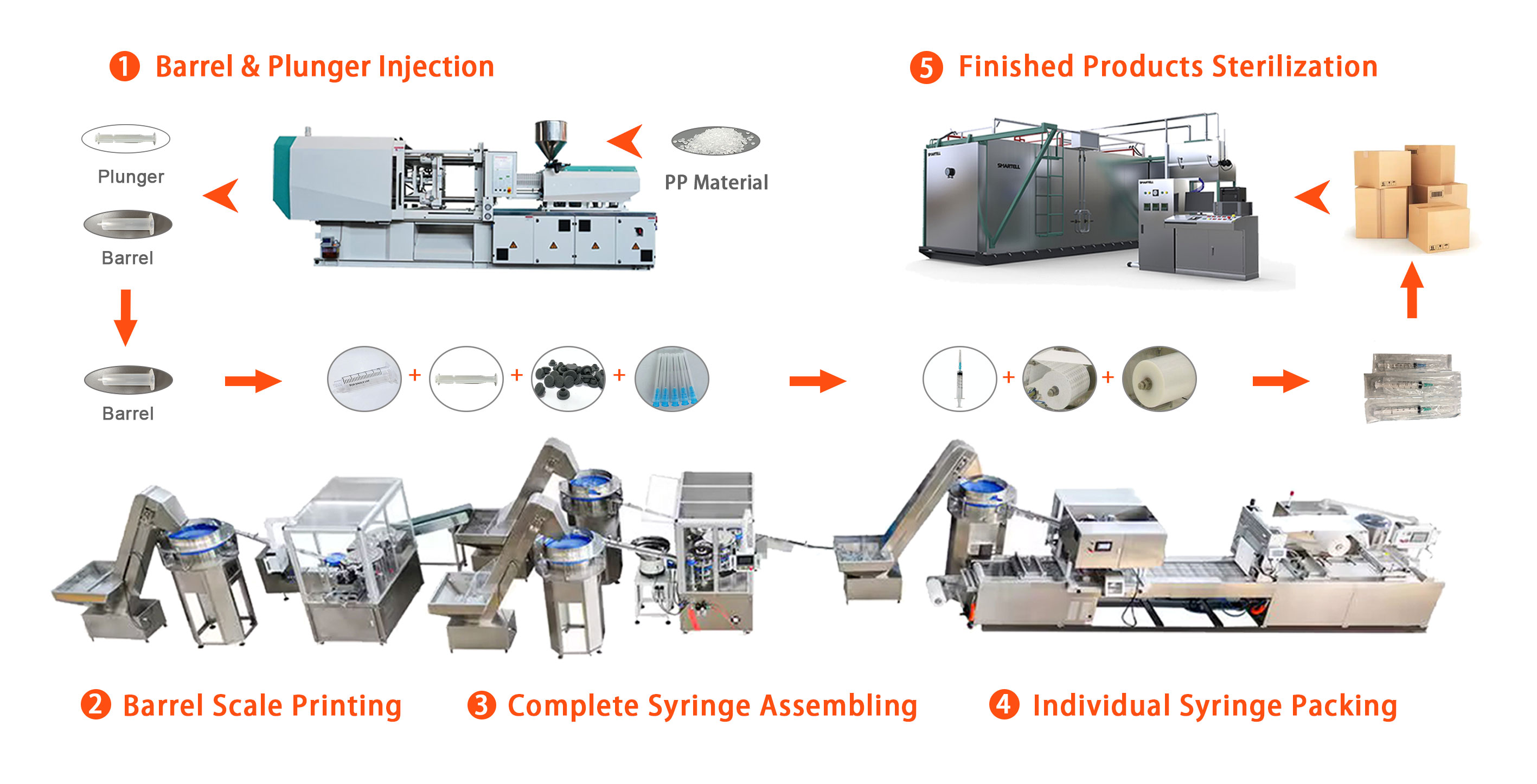

1. Injection Molding

The syringe barrel and plunger are formed by high-precision molds installed on the injection molding machine. Hot-melt PP material is injected into the molds. This is the most critical step, as the mold design and accuracy directly determine the final quality of the syringe.

2. Barrel Printing

Scale lines and logos are printed on the syringe barrel. Clear, durable printing improves both usability and the overall appearance of the syringe.

3. Assembly

All components—barrel, plunger, gasket, and needle—are assembled into a complete syringe. A stable, high-speed assembly machine significantly increases daily production capacity.

4. Packing

Because syringes must remain clean before leaving the clean room, each set requires individual packing. This is done by an automatic blister packing machine or ribbon packing machine, depending on market preference. After individual packing, the syringes are placed into boxes and cartons.

5. Sterilization

To ensure sterility and safety, packed syringes undergo ethylene oxide (ETO) sterilization before entering the market. Optional systems such as preheating units can shorten the sterilization cycle, and residual gas treatment systems can help meet higher environmental standards.