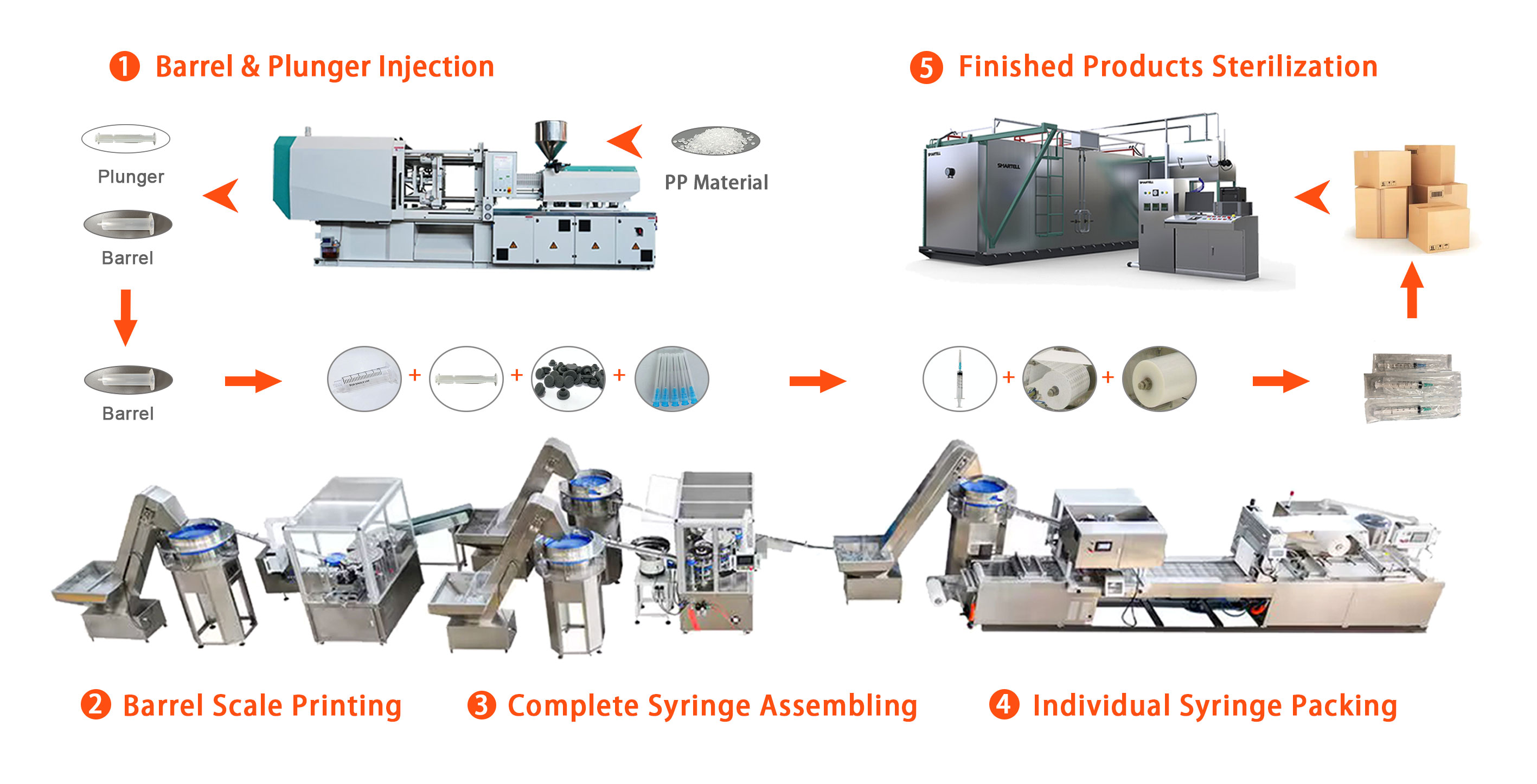

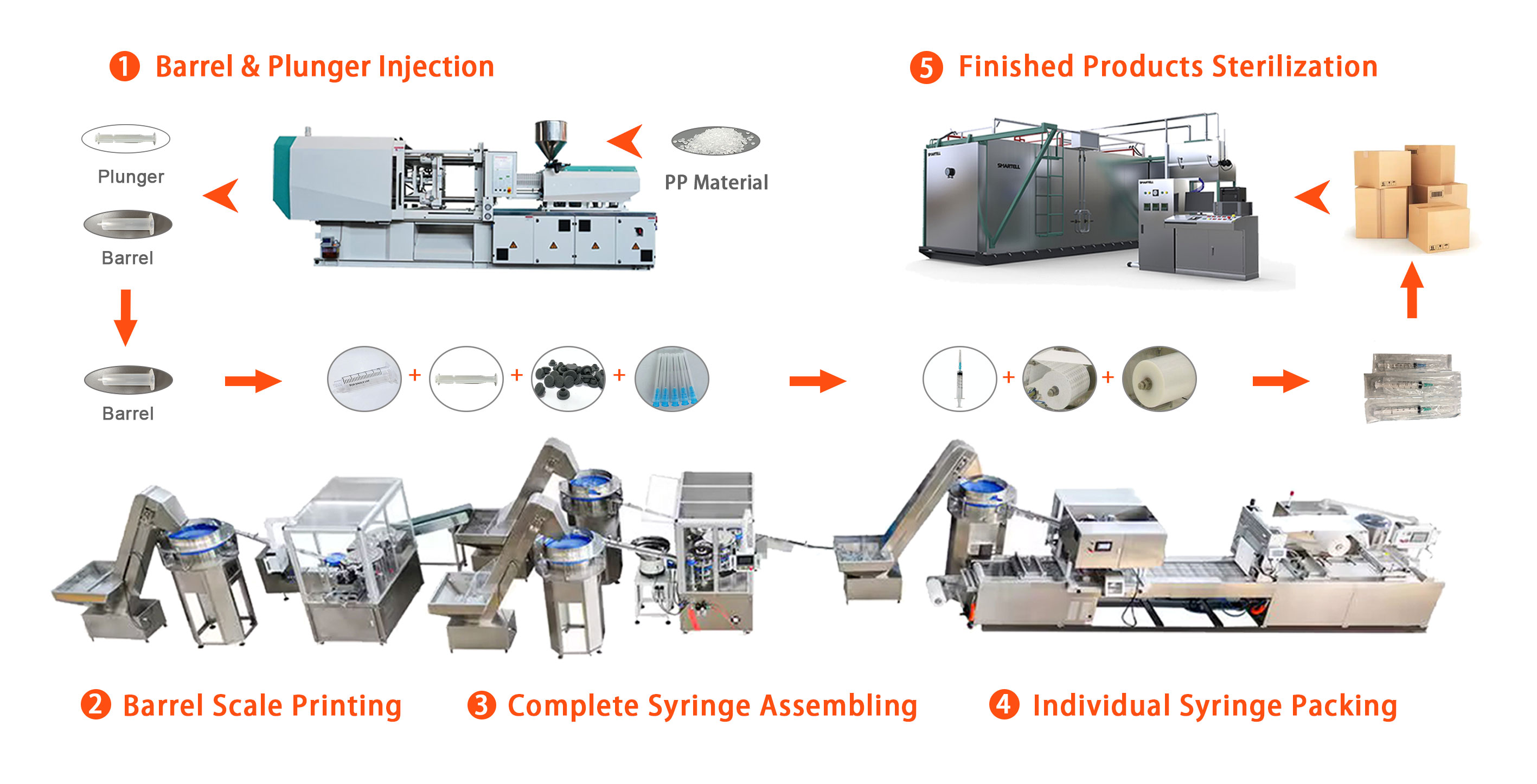

The SMARTELL syringe production line offers a fully customizable solution for different markets and factory sizes. Each section—including injection molding, printing, assembly, packing, and ETO sterilization—can be tailored to your required syringe sizes, capacities, mold designs, and automation levels. Whether you need a small starter line or a high-speed system, SMARTELL provides customized layouts, equipment options, and technical support to help you build an efficient and reliable syringe factory.

| Availability: | |

|---|---|

| Quantity: | |

SMT

SMARTELL

High-Efficiency Fully Automated Syringe Production Line for Medical Institutions

We provide a complete turnkey solution for syringe factory set up, including plant layout design, equipment selection, installation, and training. Our syringe production line covers the entire process: injection molding, printing, assembly, inspection, and packaging. All syringe making machines are built using high-quality components, offering long service life and low maintenance costs. This integrated syringe production equipment helps clients start production quickly and confidently, even with limited experience. It is the perfect choice for investors entering the medical device industry.

High-Efficiency Fully Automated Syringe Production Line for Medical Institutions

We provide a complete turnkey solution for syringe factory set up, including plant layout design, equipment selection, installation, and training. Our syringe production line covers the entire process: injection molding, printing, assembly, inspection, and packaging. All syringe making machines are built using high-quality components, offering long service life and low maintenance costs. This integrated syringe production equipment helps clients start production quickly and confidently, even with limited experience. It is the perfect choice for investors entering the medical device industry.