| Availability: | |

|---|---|

| Quantity: | |

SMT

SMARTELL

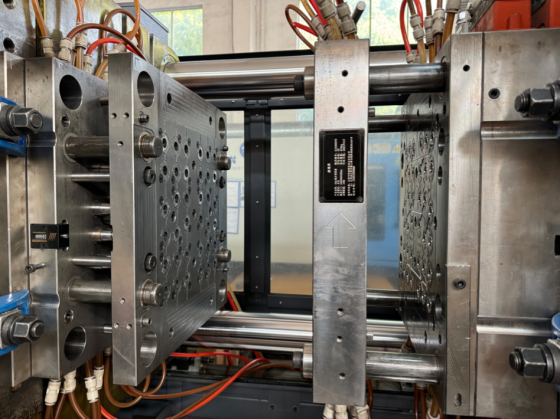

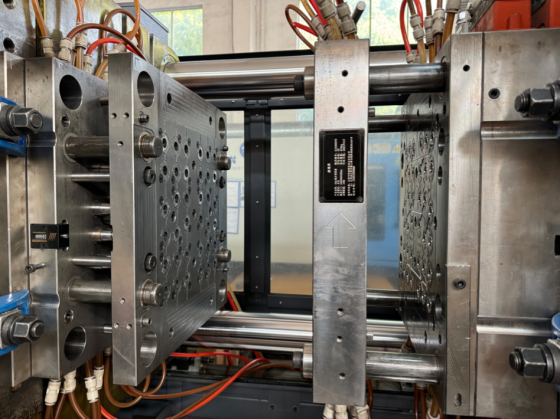

High Precision Disposable Syringe Barrel Mold for Medical Use

To meet medical application requirements, SMARTELL syringe barrel molds are manufactured using high-accuracy CNC machining and fine cavity polishing. This ensures uniform wall thickness, smooth barrel interior, and stable molding quality, which are critical for safe and accurate injection use.

The mold supports common syringe sizes such as 1ml, 3ml, 5ml, 10ml, and 20ml. Multi-cavity configurations are designed according to production needs, balancing output efficiency and molding stability. Optimized cooling channels and robust mold structure help reduce cycle time and maintain consistent performance during continuous operation. All molds are suitable for medical-grade polypropylene materials and compatible with cleanroom production environments.

![]()

Business Flow Chat

1.Enquiry | Our customers send drawing or 3D with detail information to us. |

↓ | |

2. Quote | According to the details,we make an offer. |

↓ | |

3. Negotiation | The material,delivery time,payment ,price and ect. |

↓ | |

4.Place an order | Contract Examing&Commenting. Customers do the first payment. |

↓ | |

5.Mould Design | Mould Structure Drawing and Auditing. |

↓ | |

6.Mould Make | Before making,we send design to customer to approve. |

↓ | |

7.Test Sample | We send the test sample to customer until meet customers'requests. |

↓ | |

8.Delivery | Delivery by sea or according to customer's requirment |

![]()

Syringe Barrel Mold

High Precision Disposable Syringe Barrel Mold for Medical Use

To meet medical application requirements, SMARTELL syringe barrel molds are manufactured using high-accuracy CNC machining and fine cavity polishing. This ensures uniform wall thickness, smooth barrel interior, and stable molding quality, which are critical for safe and accurate injection use.

The mold supports common syringe sizes such as 1ml, 3ml, 5ml, 10ml, and 20ml. Multi-cavity configurations are designed according to production needs, balancing output efficiency and molding stability. Optimized cooling channels and robust mold structure help reduce cycle time and maintain consistent performance during continuous operation. All molds are suitable for medical-grade polypropylene materials and compatible with cleanroom production environments.

![]()

Business Flow Chat

1.Enquiry | Our customers send drawing or 3D with detail information to us. |

↓ | |

2. Quote | According to the details,we make an offer. |

↓ | |

3. Negotiation | The material,delivery time,payment ,price and ect. |

↓ | |

4.Place an order | Contract Examing&Commenting. Customers do the first payment. |

↓ | |

5.Mould Design | Mould Structure Drawing and Auditing. |

↓ | |

6.Mould Make | Before making,we send design to customer to approve. |

↓ | |

7.Test Sample | We send the test sample to customer until meet customers'requests. |

↓ | |

8.Delivery | Delivery by sea or according to customer's requirment |

![]()

Syringe Barrel Mold