Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

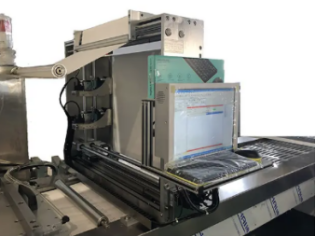

High-Speed Soft Blister Packing Machine for Syringes: Efficient and Customized Packaging Solutions

In the medical industry, the packaging process plays a crucial role in ensuring the safety, integrity, and efficiency of medical products. One of the key technologies used for packaging syringes is the soft blister packing machine, which offers a reliable and cost-effective solution for syringes of various sizes. Whether the syringes come with needles attached or are packaged separately, these machines provide the flexibility and precision required for high-quality packaging.

A soft blister packing machine for syringes is equipped with customized cavity molds designed to accommodate syringes in different sizes. This adaptability is essential since syringes come in various volumes, such as 1ml, 2ml, 3ml, 5ml, 10ml, 20ml, 30ml, 50ml, and 60ml. Each syringe size requires a specific mold to ensure proper fit and protection. These molds can be customized to precisely match the dimensions of each syringe, ensuring efficient packing and preventing any damage during the packing process.

One of the key advantages of soft blister packing machines is the flexibility they offer when it comes to packaging syringes with or without needles. The machine can either pack the syringes with the needles attached directly to the syringes or place the needles beside the syringes for packaging. This flexibility caters to various packaging preferences and regulatory requirements, ensuring that the syringes are packed in a way that best suits the end user’s needs.

Efficiency is a key factor in modern manufacturing, and the high-speed soft blister packing machine ensures that syringes are packaged quickly without compromising on quality. The packing rate varies based on the syringe size, allowing buyers to select the optimal machine settings for their production volume:

For 2-5ml syringes, the machine achieves a packing rate of 220 syringes per minute, equating to an impressive 13,200 syringes per hour.

For 1ml and 10ml syringes, the packing rate is 180 syringes per minute, or 10,080 syringes per hour.

For 20-60ml syringes, the packing rate is slightly lower at 130 syringes per minute, but still highly efficient, with a total of 7,800 syringes per hour.

This high-speed functionality is crucial for large-scale manufacturing and ensures that production meets the demands of the medical market.

To further enhance the efficiency of the packaging process, the soft blister packing machine can be equipped with various auxiliary equipment:

HP Ink Jet Coder: This device is essential for printing important information such as the date and lot number on the blister paper during the packaging process. This ensures traceability and compliance with regulatory standards.

Syringe Auto Loader: The machine can also be integrated with an auto loader, which automatically loads the syringes into the packing system. This feature significantly reduces labor costs by eliminating the need for 3-4 workers, enhancing the overall efficiency of the production line.

It’s important to note that while the soft blister packing machine provides all the required functionalities for packing syringes, the packing paper and film roll need to be prepared separately by the buyer. The quality and type of packaging material chosen will affect the overall performance of the packing machine, as well as the safety and durability of the final packaged syringes.

The soft blister packing machine for syringes is an indispensable tool for the medical industry, offering high-speed, customized, and efficient packaging solutions for syringes of all sizes. With the option to pack syringes with or without needles, integrated auxiliary equipment like ink jet coders and auto loaders, and the ability to handle various syringe sizes with tailored molds, this machine is designed to meet the diverse needs of modern manufacturing processes. By combining speed, flexibility, and precision, this machine helps manufacturers deliver high-quality, well-packaged syringes that are ready for distribution and use.