| Availability: | |

|---|---|

| Quantity: | |

SMT

SMARTELL

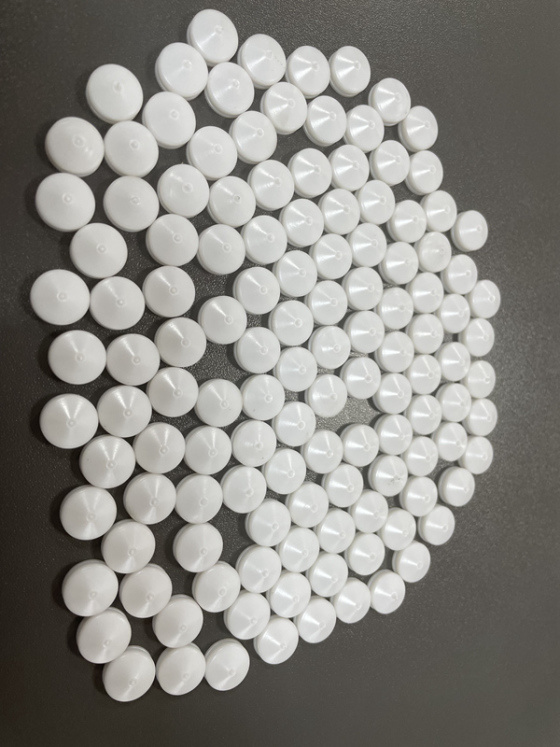

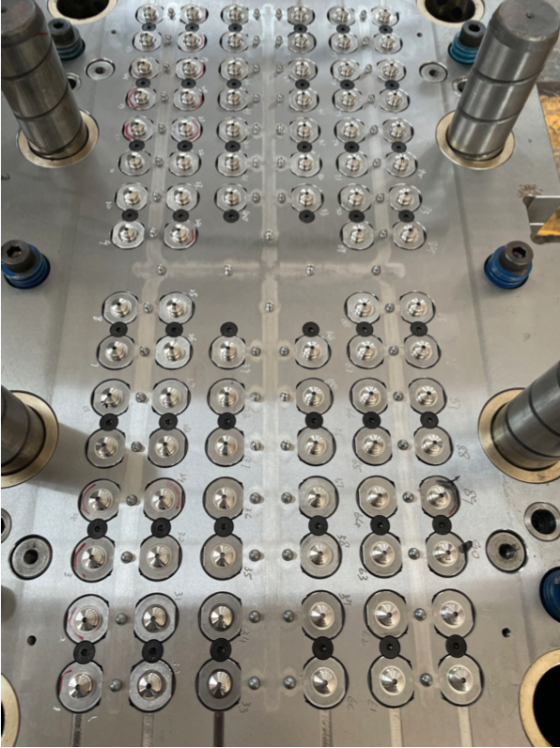

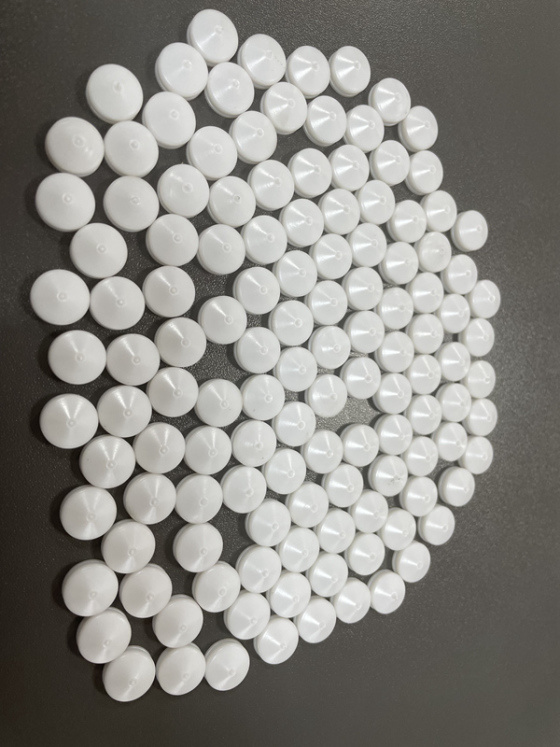

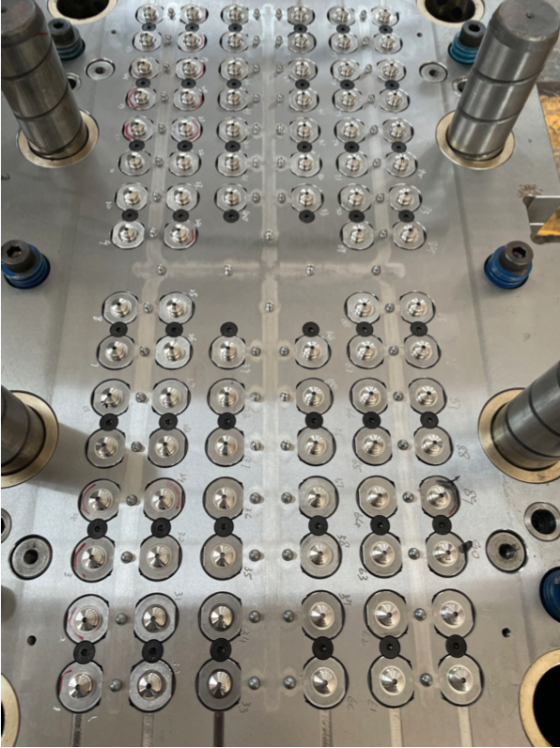

Disposable Syringe Plunger Mold with High Cavitation Design

Our gasket molds are compatible with TPE materials commonly used in medical applications. Mold designs focus on precise dimensional control and uniform compression to meet strict medical standards.

We offer multi-cavity gasket molds optimized for high output production while maintaining excellent consistency. Mold structures are designed to reduce material waste and simplify demolding, ensuring stable production efficiency.

SMARTELL provides technical support for material selection, mold testing, and gasket performance optimization to help customers achieve reliable syringe assembly and sealing performance.

![]()

Business Flow Chat

1.Enquiry | Our customers send drawing or 3D with detail information to us. |

↓ | |

2. Quote | According to the details,we make an offer. |

↓ | |

3. Negotiation | The material,delivery time,payment ,price and ect. |

↓ | |

4.Place an order | Contract Examing&Commenting. Customers do the first payment. |

↓ | |

5.Mould Design | Mould Structure Drawing and Auditing. |

↓ | |

6.Mould Make | Before making,we send design to customer to approve. |

↓ | |

7.Test Sample | We send the test sample to customer until meet customers'requests. |

↓ | |

8.Delivery | Delivery by sea or according to customer's requirment |

![]()

Syringe Gasket Mold

Disposable Syringe Plunger Mold with High Cavitation Design

Our gasket molds are compatible with TPE materials commonly used in medical applications. Mold designs focus on precise dimensional control and uniform compression to meet strict medical standards.

We offer multi-cavity gasket molds optimized for high output production while maintaining excellent consistency. Mold structures are designed to reduce material waste and simplify demolding, ensuring stable production efficiency.

SMARTELL provides technical support for material selection, mold testing, and gasket performance optimization to help customers achieve reliable syringe assembly and sealing performance.

![]()

Business Flow Chat

1.Enquiry | Our customers send drawing or 3D with detail information to us. |

↓ | |

2. Quote | According to the details,we make an offer. |

↓ | |

3. Negotiation | The material,delivery time,payment ,price and ect. |

↓ | |

4.Place an order | Contract Examing&Commenting. Customers do the first payment. |

↓ | |

5.Mould Design | Mould Structure Drawing and Auditing. |

↓ | |

6.Mould Make | Before making,we send design to customer to approve. |

↓ | |

7.Test Sample | We send the test sample to customer until meet customers'requests. |

↓ | |

8.Delivery | Delivery by sea or according to customer's requirment |

![]()

Syringe Gasket Mold