Views: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

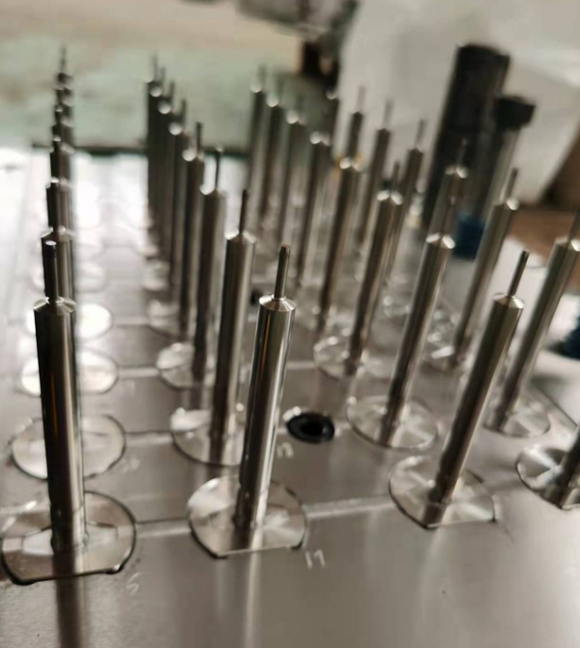

SMARTELL TECHNOLOGY CO., LTD. high-precision syringe molds, engineered specifically for medical-grade injection molding. The new mold series delivers greater durability, accuracy, and stability—meeting the extreme precision required for syringe barrel, plunger, and gasket production.

Syringe molds are fundamentally different from ordinary plastic molds. Because syringes are used for medical injection and drug delivery, their components must meet strict international standards for clarity, safety, dimensional accuracy, smoothness, and sealing performance. This makes syringe molds one of the most precision-dependent mold categories in the plastic injection molding industry.

Unlike general consumer plastic products, syringes must ensure:

Perfect transparency for visual medication check

Smooth inner surface for friction-free plunger movement

Precise dosing accuracy and wall thickness

Stable luer lock / luer slip dimensional fit

Zero flash, zero burr, and no flow marks

Consistent sealing performance between barrel and plunger

Even the smallest dimensional deviation can lead to leakage, inaccurate measurement, or increased friction—making syringe molds far more complex than traditional plastic molds.

Most syringes are produced using medical-grade polypropylene (PP), chosen for its:

High clarity

Biocompatibility

Good toughness

Low friction

Excellent processability

Resistance to sterilization methods (ETO, Gamma, Steam)*

Because the resin must flow smoothly into thin-wall areas, the mold runner system, venting, and gating design require expert engineering.

To meet long-term high-volume production demands, SMARTELL uses top-tier mold steels, including:

S136 (Sweden)

P20

These materials offer:

High corrosion resistance

Excellent polishability for transparency

High hardness & wear resistance

Long mold lifecycle

Easy maintenance

Stable performance during fast injection cycles

With proper maintenance, syringe molds can reach 3 million shots, depending on resin and process conditions.

| Feature | Syringe Molds | Regular Plastic Molds |

|---|---|---|

| Precision | Micron-level | General tolerance |

| Surface Finish | Mirror polish for transparency | Standard polish |

| Complexity | High due to tight dimensions | Medium to low |

| Material Quality | Premium corrosion-resistant steel | Standard tool steel |

| Product Requirements | Medical-grade, zero defects | General consumer grade |

| Production Volume | Ultra high-volume | Variable |

| Safety Standard | Medical compliance | Non-medical |

Syringe molds are in a class of their own due to the medical industry’s strict requirements for safety, clarity, and precision.

With years of experience in the medical equipment industry, SMARTELL TECHNOLOGY CO., LTD. continues to supply high-performance syringe molds that support global manufacturers with:

Higher production output

Longer mold lifespan

Reduced maintenance cost

Faster cycle times

Excellent barrel transparency

High accuracy for luer lock / luer slip connection

Smartell remains committed to innovation, precision manufacturing, and delivering world-class molds for medical syringe production.