| Availability: | |

|---|---|

| Quantity: | |

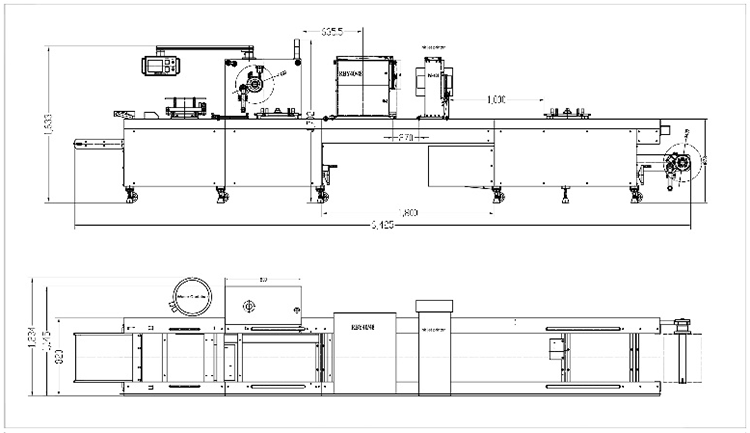

SMT-4420

Smartell

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

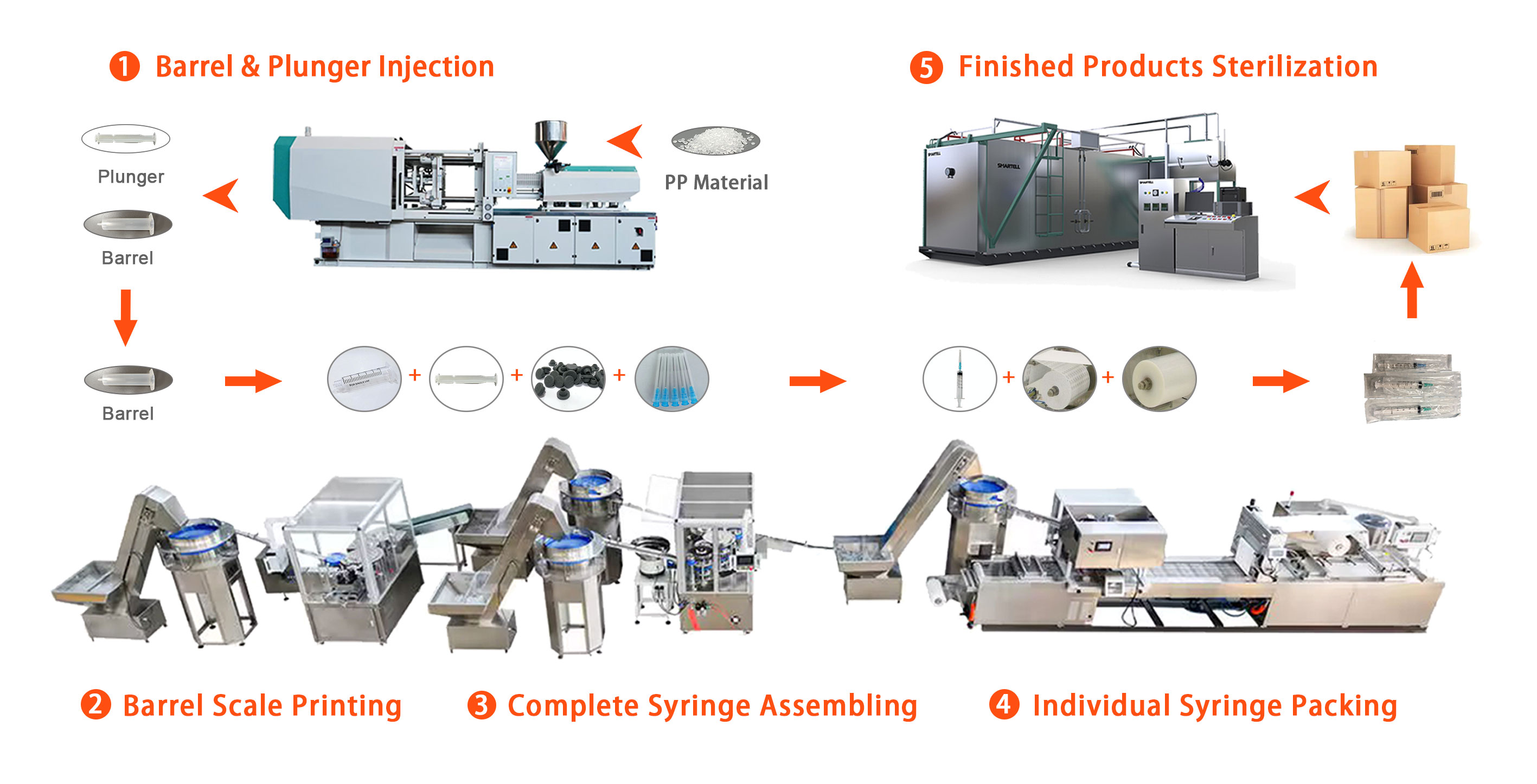

The Essential Role of Syringe Blister Packing Machines in the Medical Industry

In the fast-evolving medical sector, packaging plays a crucial role in ensuring product integrity, safety, and efficiency. Among the different packaging solutions, syringe blister packing machines have become indispensable for the packaging of syringe. These machines not only preserve the sterility of syringes but also enhance the convenience and safety of handling and transportation.

A syringe blister packing machine is a specialized piece of equipment designed to package syringes. These machines are engineered to meet strict medical standards and requirements, ensuring that syringes remain sterile and secure during storage, distribution, and use. The blister pack typically consists of a thermoformed plastic cavity that holds the syringe securely, with a heat-sealed foil lid providing protection against contaminants.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 15 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

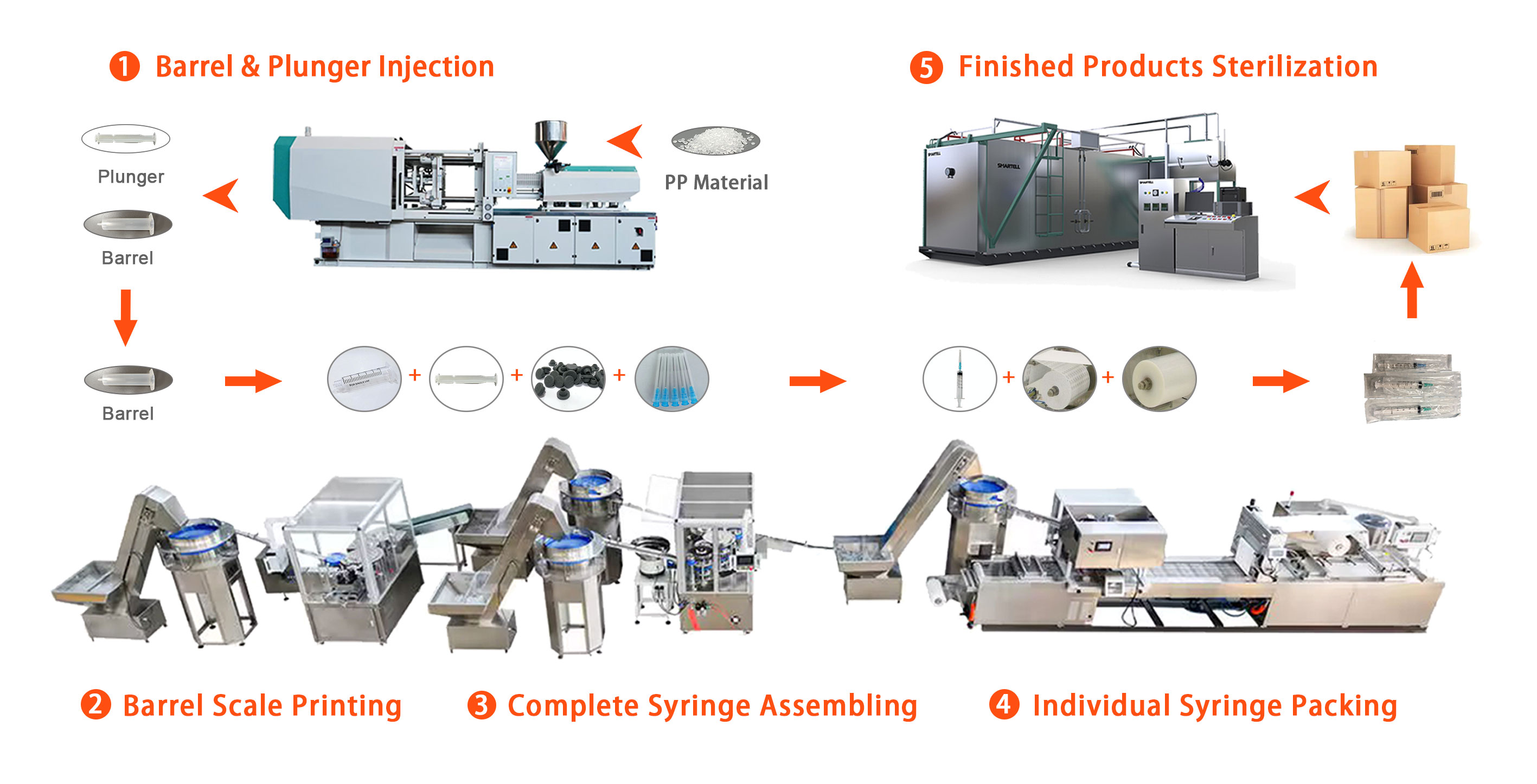

The Essential Role of Syringe Blister Packing Machines in the Medical Industry

In the fast-evolving medical sector, packaging plays a crucial role in ensuring product integrity, safety, and efficiency. Among the different packaging solutions, syringe blister packing machines have become indispensable for the packaging of syringe. These machines not only preserve the sterility of syringes but also enhance the convenience and safety of handling and transportation.

A syringe blister packing machine is a specialized piece of equipment designed to package syringes. These machines are engineered to meet strict medical standards and requirements, ensuring that syringes remain sterile and secure during storage, distribution, and use. The blister pack typically consists of a thermoformed plastic cavity that holds the syringe securely, with a heat-sealed foil lid providing protection against contaminants.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 15 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

How Does a Syringe Blister Packaging Machine Work?

Syringe blister packaging machines operate on a highly automated system, designed to handle large volumes of syringes with precision. The process generally involves the following steps:

1.Feeding: The syringes are fed into the machine from a bulk supply or from an automated feeding system.

2.Forming: The machine uses heat and pressure to form the plastic blister cavities that will hold each syringe securely.

3.Placing: The syringes are placed into the formed blisters by an automated placement system. In some cases, robots are used for high-speed placement and handling.

4.Sealing: The plastic blister is sealed with a foil lid to ensure the syringe remains sterile. This can be done using heat-sealing technology.

5.Cutting and Packaging: The finished blister packs are then cut from the larger sheet, inspected, and packaged for distribution.

The entire process is highly controlled to ensure that syringes are not damaged during packaging, and that they meet all regulatory requirements for pharmaceutical packaging.

How Does a Syringe Blister Packaging Machine Work?

Syringe blister packaging machines operate on a highly automated system, designed to handle large volumes of syringes with precision. The process generally involves the following steps:

1.Feeding: The syringes are fed into the machine from a bulk supply or from an automated feeding system.

2.Forming: The machine uses heat and pressure to form the plastic blister cavities that will hold each syringe securely.

3.Placing: The syringes are placed into the formed blisters by an automated placement system. In some cases, robots are used for high-speed placement and handling.

4.Sealing: The plastic blister is sealed with a foil lid to ensure the syringe remains sterile. This can be done using heat-sealing technology.

5.Cutting and Packaging: The finished blister packs are then cut from the larger sheet, inspected, and packaged for distribution.

The entire process is highly controlled to ensure that syringes are not damaged during packaging, and that they meet all regulatory requirements for pharmaceutical packaging.

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.