| Availability: | |

|---|---|

| Quantity: | |

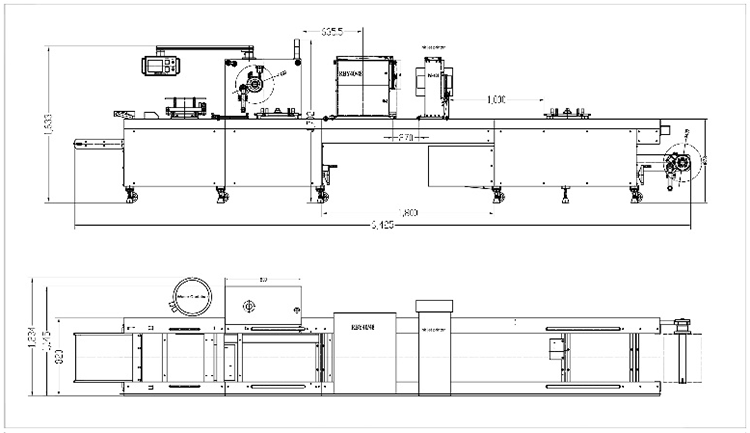

SMT-4420

Smartell

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Types of Syringe Blister Packaging Machines

1. Semi-Automatic Syringe Packing Machines: These machines require some manual intervention, typically for feeding syringes into the system, but the rest of the process is automated. They are more affordable and are often used in smaller production environments.

2. Fully Automatic Syringe Packing Machines: Fully automated machines are designed to handle high-volume production. They include advanced features such as automatic syringe feeding, precise blister forming, and efficient sealing systems, making them ideal for large medical companies.

3. Syringe Blister Packing Lines: These are integrated systems that combine multiple machines and processes to create a fully automated line for syringe blister packaging. A syringe blister packing line may include modules for syringe inspection, labeling, serialization, and even end-of-line packaging, ensuring a seamless workflow from start to finish.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

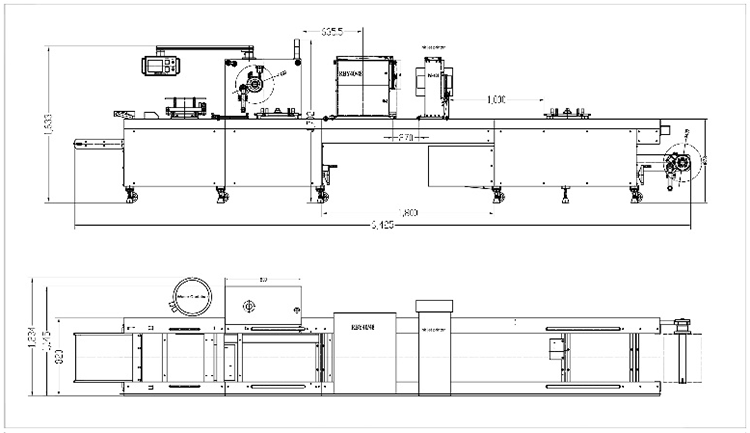

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Types of Syringe Blister Packaging Machines

1. Semi-Automatic Syringe Packing Machines: These machines require some manual intervention, typically for feeding syringes into the system, but the rest of the process is automated. They are more affordable and are often used in smaller production environments.

2. Fully Automatic Syringe Packing Machines: Fully automated machines are designed to handle high-volume production. They include advanced features such as automatic syringe feeding, precise blister forming, and efficient sealing systems, making them ideal for large medical companies.

3. Syringe Blister Packing Lines: These are integrated systems that combine multiple machines and processes to create a fully automated line for syringe blister packaging. A syringe blister packing line may include modules for syringe inspection, labeling, serialization, and even end-of-line packaging, ensuring a seamless workflow from start to finish.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

Automatic Medical Use Syringe Blister Packing Machine

Advantages of Syringe Blister Packaging

1. Protection and Sterility: One of the most significant advantages of syringe blister packaging is its ability to maintain the sterility of syringes. The sealed blister pack protects the syringe from contamination and damage, ensuring that the medication inside remains safe and effective.

2. Tamper-Evident Features: The sealing process creates a tamper-evident barrier that ensures the syringe has not been altered or tampered with, providing an additional layer of security for patients and healthcare providers.

3. Convenience: The blister packs are easy to handle, store, and transport. They provide an efficient solution for packaging pre-filled syringes, which are increasingly in demand due to their convenience in administering medications.

4. Regulatory Compliance: Syringe blister packaging machines are designed to meet stringent pharmaceutical packaging regulations, including those for quality control, traceability, and serialization. These features help pharmaceutical manufacturers comply with global standards.

5. Cost-Efficiency: Fully automated machines reduce labor costs and improve throughput, making it easier for manufacturers to scale production without sacrificing quality or sterility.

Automatic Medical Use Syringe Blister Packing Machine

Advantages of Syringe Blister Packaging

1. Protection and Sterility: One of the most significant advantages of syringe blister packaging is its ability to maintain the sterility of syringes. The sealed blister pack protects the syringe from contamination and damage, ensuring that the medication inside remains safe and effective.

2. Tamper-Evident Features: The sealing process creates a tamper-evident barrier that ensures the syringe has not been altered or tampered with, providing an additional layer of security for patients and healthcare providers.

3. Convenience: The blister packs are easy to handle, store, and transport. They provide an efficient solution for packaging pre-filled syringes, which are increasingly in demand due to their convenience in administering medications.

4. Regulatory Compliance: Syringe blister packaging machines are designed to meet stringent pharmaceutical packaging regulations, including those for quality control, traceability, and serialization. These features help pharmaceutical manufacturers comply with global standards.

5. Cost-Efficiency: Fully automated machines reduce labor costs and improve throughput, making it easier for manufacturers to scale production without sacrificing quality or sterility.

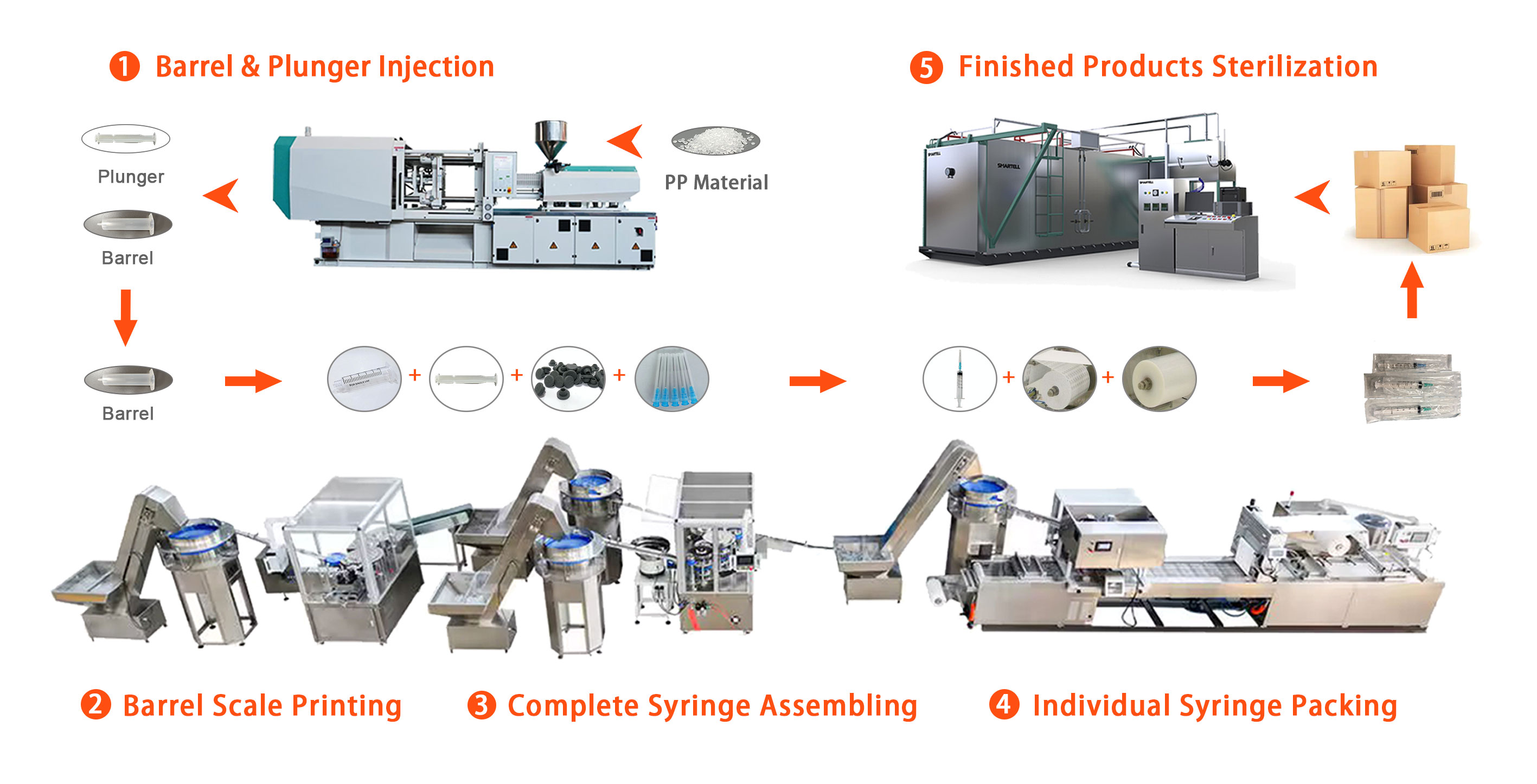

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

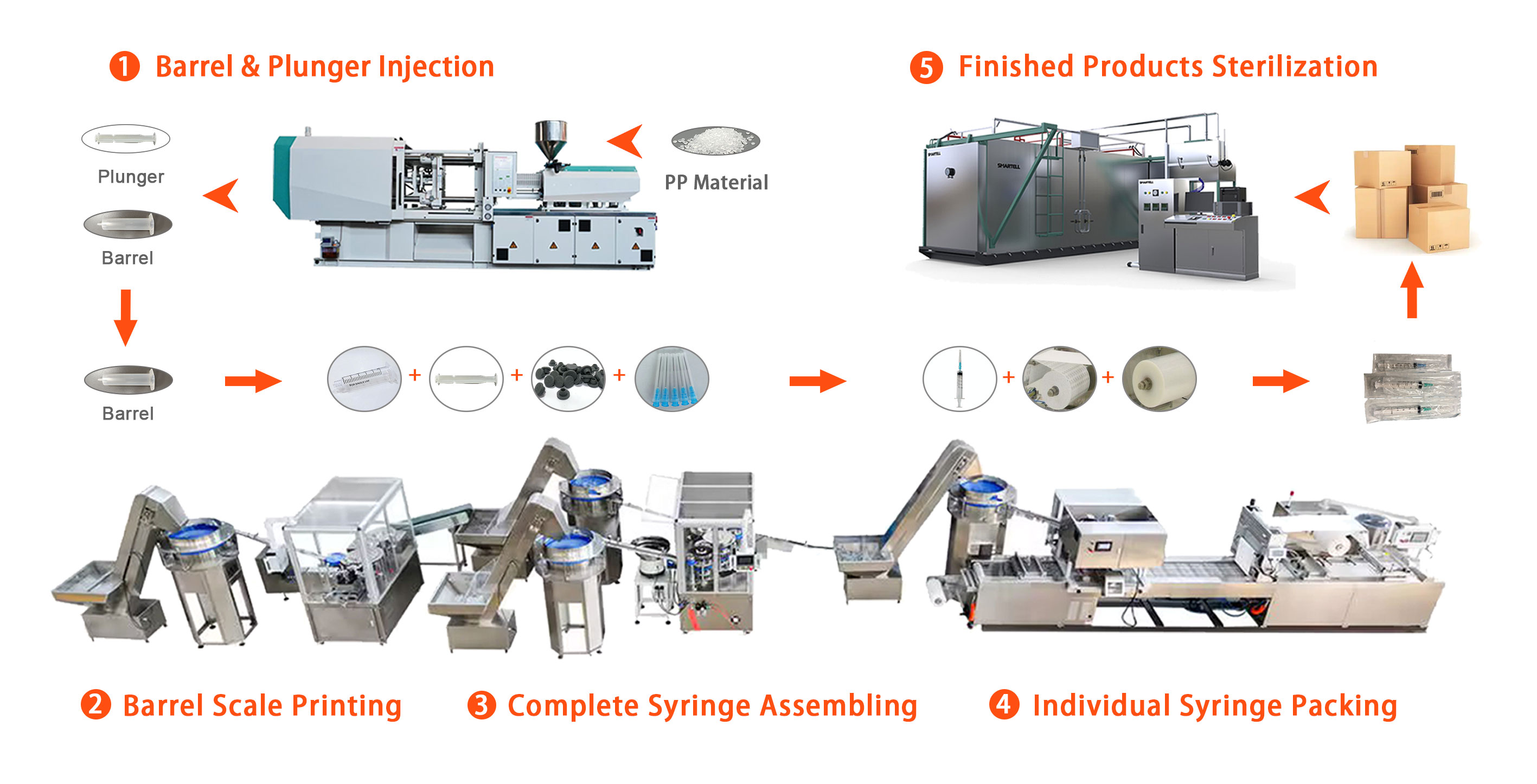

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.