| Availability: | |

|---|---|

| Quantity: | |

SMT

SMARTELL

Syringe Barrel Gasket Plunger Mould

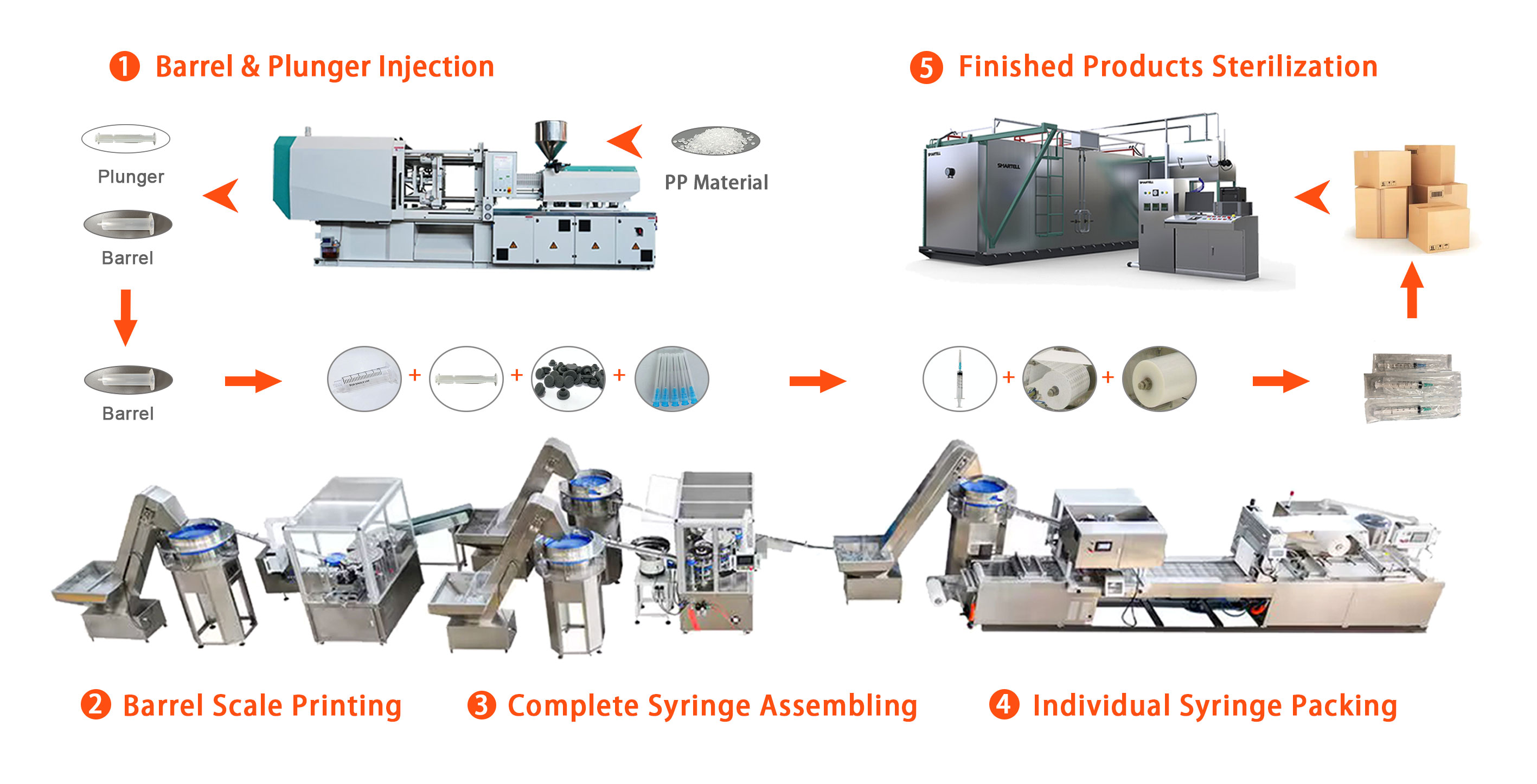

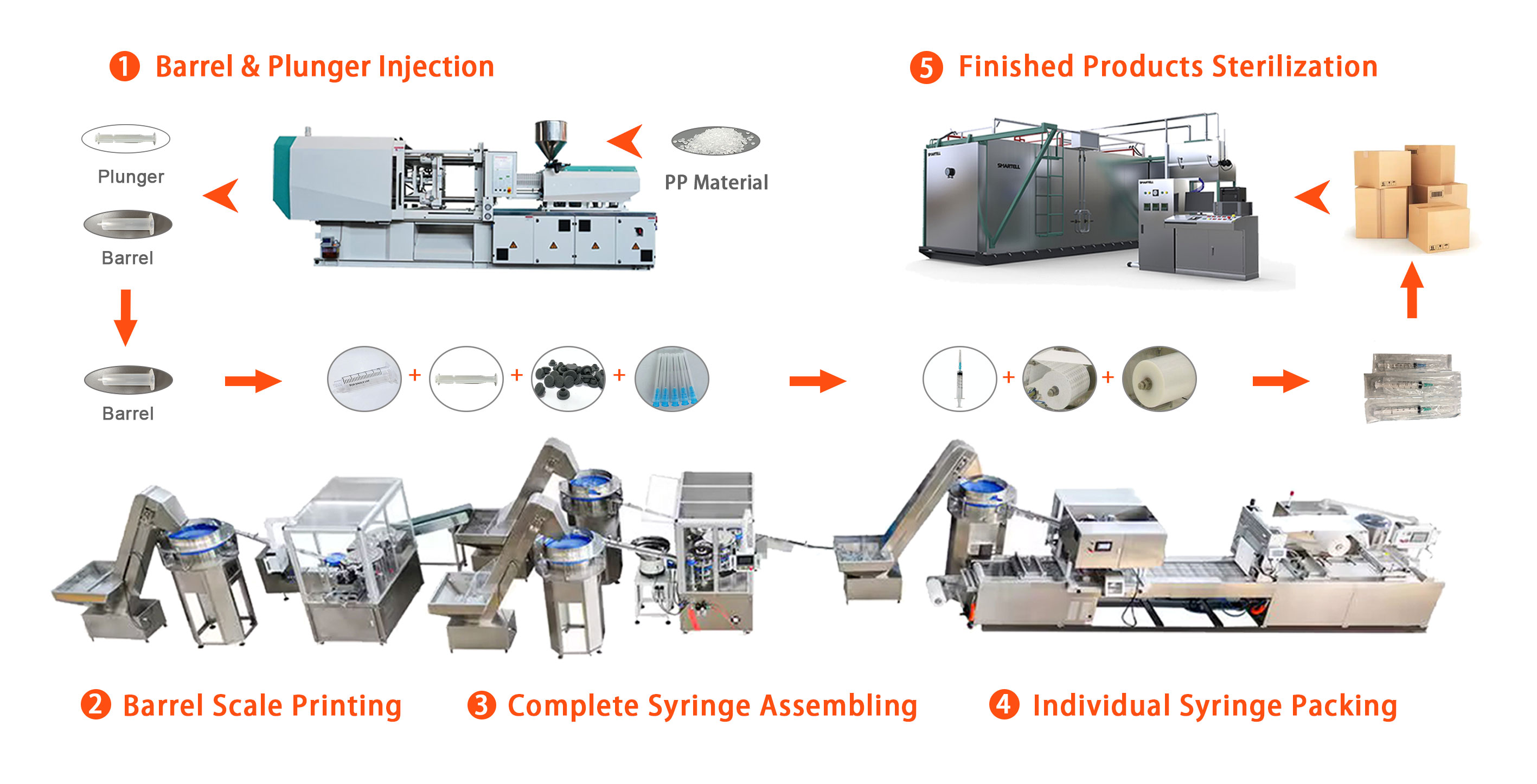

A syringe mould is a high-precision injection mould specially engineered for the mass production of disposable medical syringe components, including the barrel, plunger, and gasket. It is a core element of the syringe manufacturing process, directly affecting product accuracy, functionality, and compliance with medical standards.

The syringe barrel mould is designed to produce transparent barrels with a highly polished inner surface, precise inner diameter, and consistent wall thickness. Advanced machining and mirror-finish polishing ensure smooth plunger movement, accurate dosage capacity, and excellent transparency for clear scale reading. The mould structure guarantees dimensional stability and repeatability across large-scale production.

The plunger mould produces the plunger rod with high mechanical strength, straightness, and dimensional accuracy. The mould ensures reliable assembly with the gasket and smooth sliding performance inside the barrel without deformation or binding during use.

The gasket mould is used for molding rubber or elastomer gaskets that provide airtight sealing between the barrel and plunger. It is designed to ensure uniform elasticity, precise geometry, and consistent sealing force, maintaining leak-free performance throughout injection and withdrawal.

syringe barrel mould

syringe barrel mould

syringe plunger mould

syringe gasket mould

Syringe moulds are typically manufactured from high-grade mold steel and feature multi-cavity configurations to maximize productivity. They are often equipped with hot runner systems, precision temperature control, and optimized cooling channels to ensure efficient material flow, short cycle times, and stable product quality. With long service life, high consistency, and strict adherence to medical manufacturing requirements, syringe moulds play a critical role in producing safe, reliable, and high-quality disposable syringes.

Syringe Barrel Gasket Plunger Mould

A syringe mould is a high-precision injection mould specially engineered for the mass production of disposable medical syringe components, including the barrel, plunger, and gasket. It is a core element of the syringe manufacturing process, directly affecting product accuracy, functionality, and compliance with medical standards.

The syringe barrel mould is designed to produce transparent barrels with a highly polished inner surface, precise inner diameter, and consistent wall thickness. Advanced machining and mirror-finish polishing ensure smooth plunger movement, accurate dosage capacity, and excellent transparency for clear scale reading. The mould structure guarantees dimensional stability and repeatability across large-scale production.

The plunger mould produces the plunger rod with high mechanical strength, straightness, and dimensional accuracy. The mould ensures reliable assembly with the gasket and smooth sliding performance inside the barrel without deformation or binding during use.

The gasket mould is used for molding rubber or elastomer gaskets that provide airtight sealing between the barrel and plunger. It is designed to ensure uniform elasticity, precise geometry, and consistent sealing force, maintaining leak-free performance throughout injection and withdrawal.

syringe barrel mould

syringe barrel mould

syringe plunger mould

syringe gasket mould

Syringe moulds are typically manufactured from high-grade mold steel and feature multi-cavity configurations to maximize productivity. They are often equipped with hot runner systems, precision temperature control, and optimized cooling channels to ensure efficient material flow, short cycle times, and stable product quality. With long service life, high consistency, and strict adherence to medical manufacturing requirements, syringe moulds play a critical role in producing safe, reliable, and high-quality disposable syringes.