| Availability: | |

|---|---|

| Quantity: | |

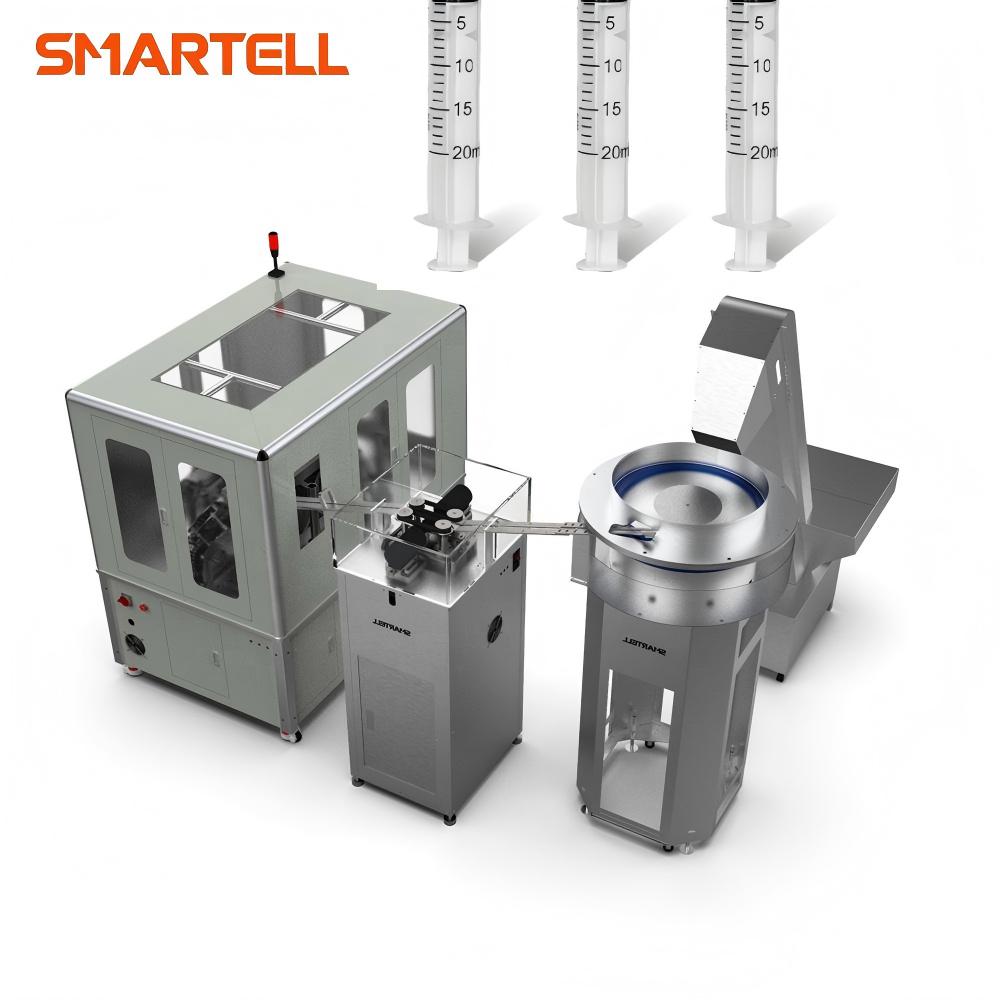

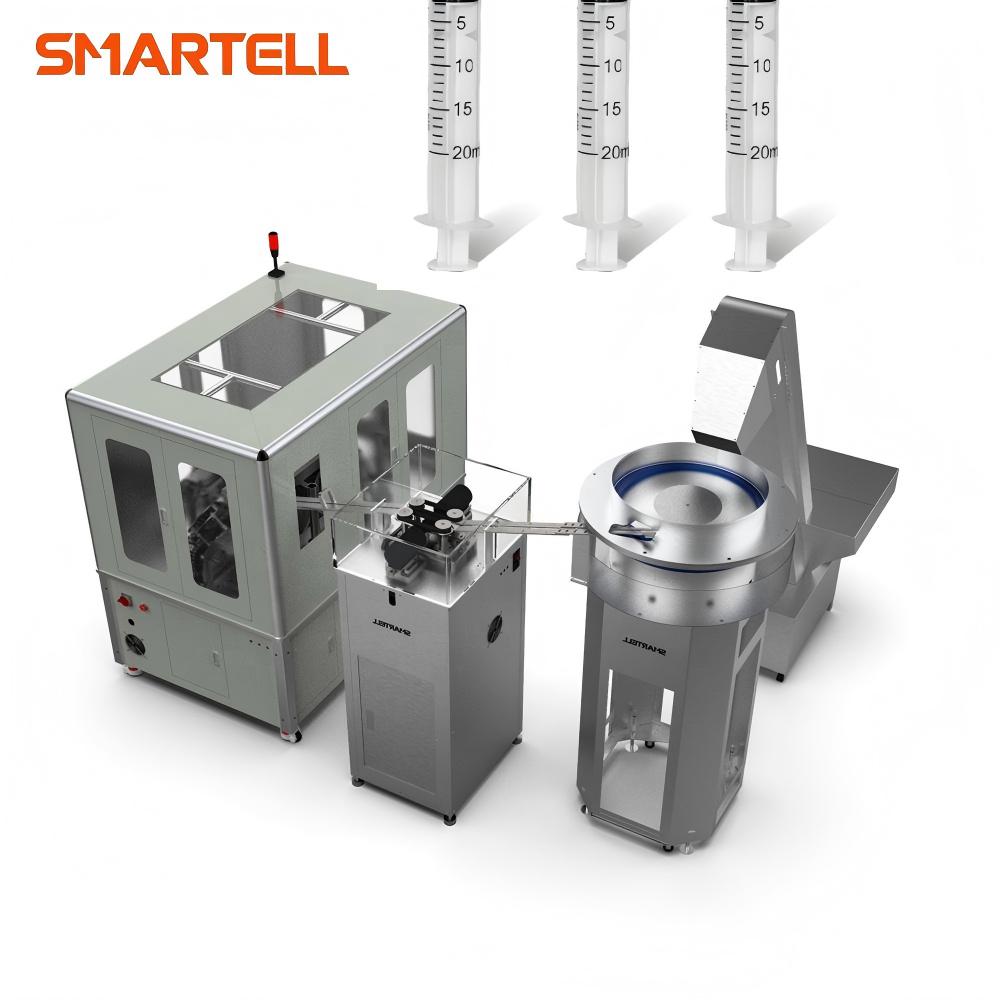

SMT-2001

SMARTELL

Uses advanced servo-driven pad printing technology to achieve accurate and consistent printing on round syringe barrels.

Ensures clear, uniform scale lines and logos even at high production speeds.

Special medical-grade ink provides excellent adhesion and resistance to alcohol, sterilization, and abrasion.

Printed marks remain clear and intact after ethylene oxide sterilization or gamma radiation.

Integrates automatic feeding, positioning, printing, drying, and discharging, minimizing manual handling.

Greatly improves efficiency and reduces labor cost.

Equipped with PLC and touch screen control, allowing easy parameter setting, fault detection, and automatic counting.

Real-time monitoring ensures stable performance and quick troubleshooting.

Optional infrared or UV curing system for rapid ink drying.

Supports continuous, 24-hour operation to meet large-scale syringe production demands.

Quick changeover design allows printing for various syringe capacities (1ml to 50ml) without complicated adjustments.

Suitable for both Luer slip and Luer lock syringe types.

Made from stainless steel and aluminum alloy, resistant to rust and easy to clean.

Designed according to GMP standards, ensuring a contamination-free printing environment.

High-quality components (imported electrical and pneumatic parts) ensure long service life and consistent performance.

Automatic alarm and stop functions protect the machine and prevent printing errors.

Uses advanced servo-driven pad printing technology to achieve accurate and consistent printing on round syringe barrels.

Ensures clear, uniform scale lines and logos even at high production speeds.

Special medical-grade ink provides excellent adhesion and resistance to alcohol, sterilization, and abrasion.

Printed marks remain clear and intact after ethylene oxide sterilization or gamma radiation.

Integrates automatic feeding, positioning, printing, drying, and discharging, minimizing manual handling.

Greatly improves efficiency and reduces labor cost.

Equipped with PLC and touch screen control, allowing easy parameter setting, fault detection, and automatic counting.

Real-time monitoring ensures stable performance and quick troubleshooting.

Optional infrared or UV curing system for rapid ink drying.

Supports continuous, 24-hour operation to meet large-scale syringe production demands.

Quick changeover design allows printing for various syringe capacities (1ml to 50ml) without complicated adjustments.

Suitable for both Luer slip and Luer lock syringe types.

Made from stainless steel and aluminum alloy, resistant to rust and easy to clean.

Designed according to GMP standards, ensuring a contamination-free printing environment.

High-quality components (imported electrical and pneumatic parts) ensure long service life and consistent performance.

Automatic alarm and stop functions protect the machine and prevent printing errors.