| Availability: | |

|---|---|

| Quantity: | |

SMT-5010

SMARTELL

Ethylene Oxide Sterilization Machine

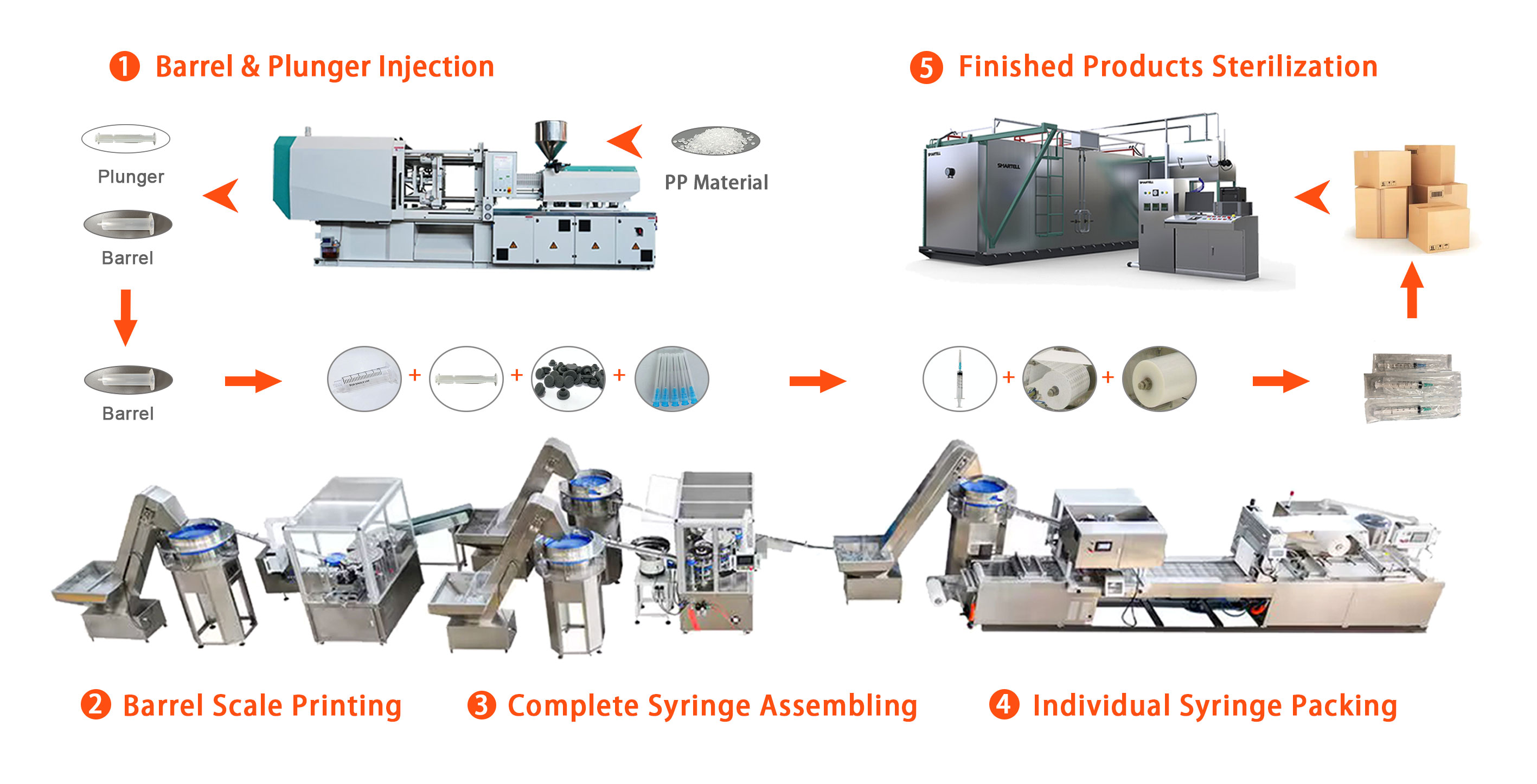

The typical ETO sterilization cycle includes the following stages:

Pre-conditioning

Syringes are placed in a controlled environment to adjust temperature and humidity, improving sterilization effectiveness.

Gas Injection

Ethylene oxide gas is introduced into the sterilization chamber at a controlled concentration.

Sterilization Holding

The gas penetrates the packaging and syringe components, destroying microorganisms at the molecular level.

Evacuation and Aeration

EO gas is removed from the chamber, and products undergo aeration to reduce EO residue to safe levels.

Ethylene Oxide Sterilization Machine

The typical ETO sterilization cycle includes the following stages:

Pre-conditioning

Syringes are placed in a controlled environment to adjust temperature and humidity, improving sterilization effectiveness.

Gas Injection

Ethylene oxide gas is introduced into the sterilization chamber at a controlled concentration.

Sterilization Holding

The gas penetrates the packaging and syringe components, destroying microorganisms at the molecular level.

Evacuation and Aeration

EO gas is removed from the chamber, and products undergo aeration to reduce EO residue to safe levels.