| Availability: | |

|---|---|

| Quantity: | |

SMT-4420

Smartell

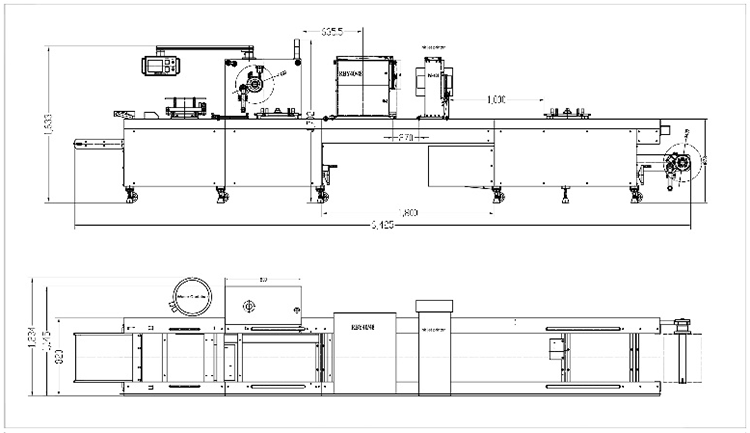

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

In the medical industry, ensuring the safety and integrity of products is paramount. Whether it's a syringe, vial, or any other delicate medical product, packaging plays a critical role in maintaining sterility, protecting against environmental damage, and making sure the product is properly presented for use. Blister packaging, specifically soft blister paper film packaging, is a popular method due to its ability to keep products safe while offering ease of handling, tamper resistance, and visible presentation. These attributes are particularly crucial for syringes, which must remain sterile and secure until they're used in medical procedures.

An Automatic Syringe PVC Blister Packing Machine is specifically designed to package syringes in PVC (polyvinyl chloride) blister packs, a material known for its protective properties and cost-effectiveness. These machines have been developed to streamline the production process, reduce human intervention, and improve packing precision, all while ensuring the safety and sterility of the medical products being packaged.

The machines are equipped with advanced technology that automatically fills, seals, and cuts the blister packs. They typically include features such as automatic loading, molding, sealing, and cutting, making them ideal for high-volume production lines in medical device manufacturing.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

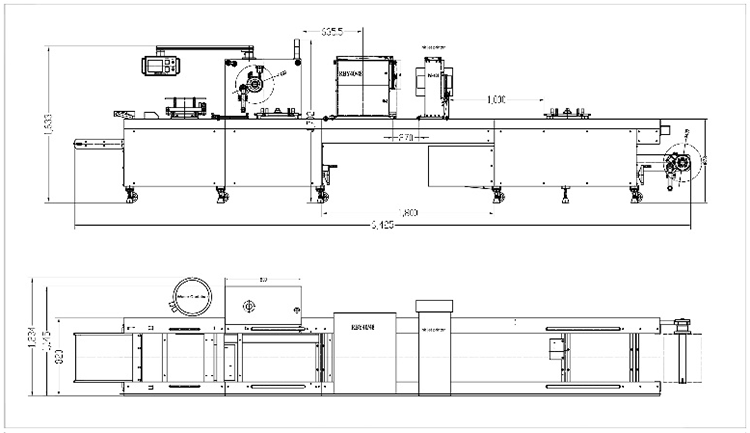

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

In the medical industry, ensuring the safety and integrity of products is paramount. Whether it's a syringe, vial, or any other delicate medical product, packaging plays a critical role in maintaining sterility, protecting against environmental damage, and making sure the product is properly presented for use. Blister packaging, specifically soft blister paper film packaging, is a popular method due to its ability to keep products safe while offering ease of handling, tamper resistance, and visible presentation. These attributes are particularly crucial for syringes, which must remain sterile and secure until they're used in medical procedures.

An Automatic Syringe PVC Blister Packing Machine is specifically designed to package syringes in PVC (polyvinyl chloride) blister packs, a material known for its protective properties and cost-effectiveness. These machines have been developed to streamline the production process, reduce human intervention, and improve packing precision, all while ensuring the safety and sterility of the medical products being packaged.

The machines are equipped with advanced technology that automatically fills, seals, and cuts the blister packs. They typically include features such as automatic loading, molding, sealing, and cutting, making them ideal for high-volume production lines in medical device manufacturing.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

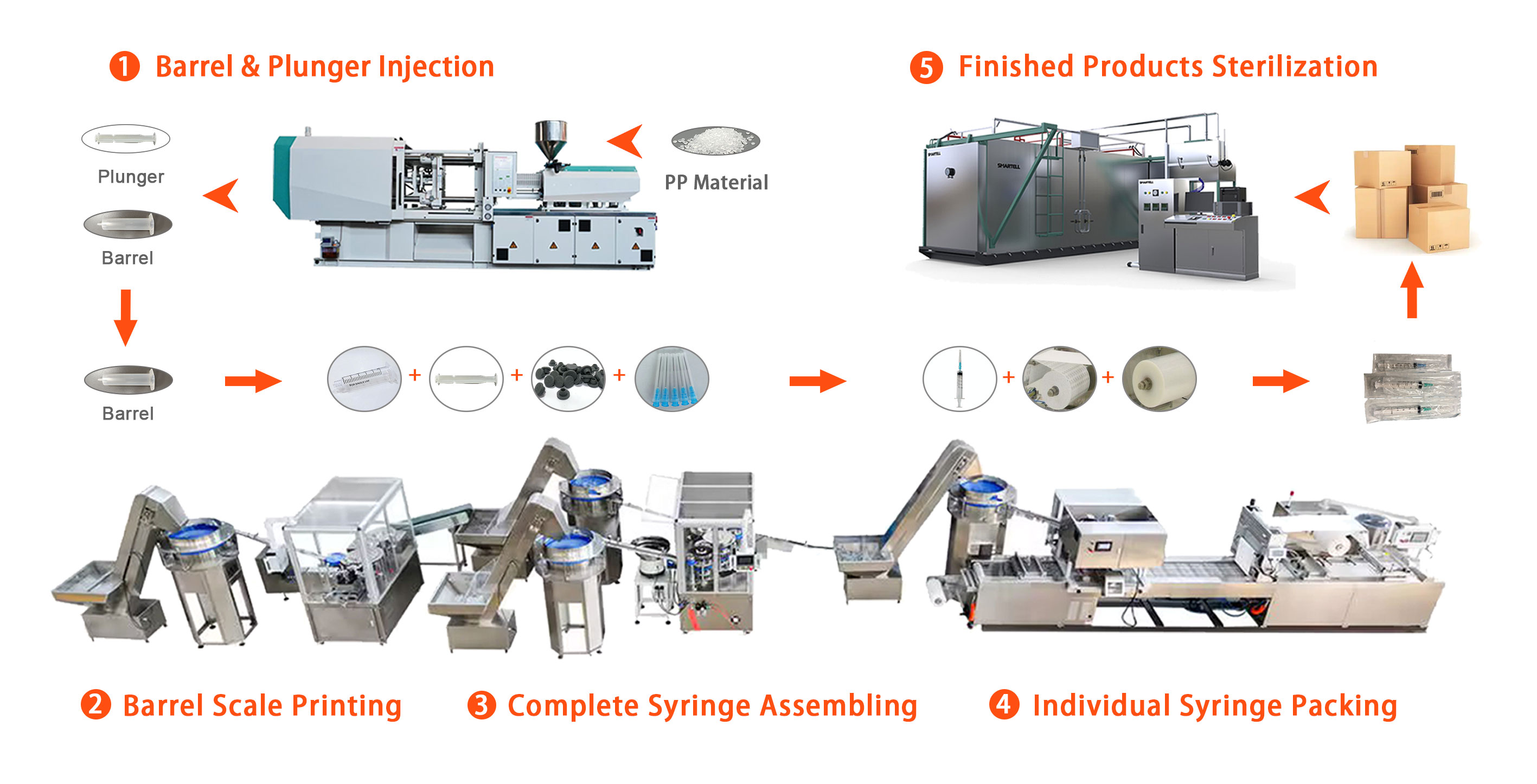

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

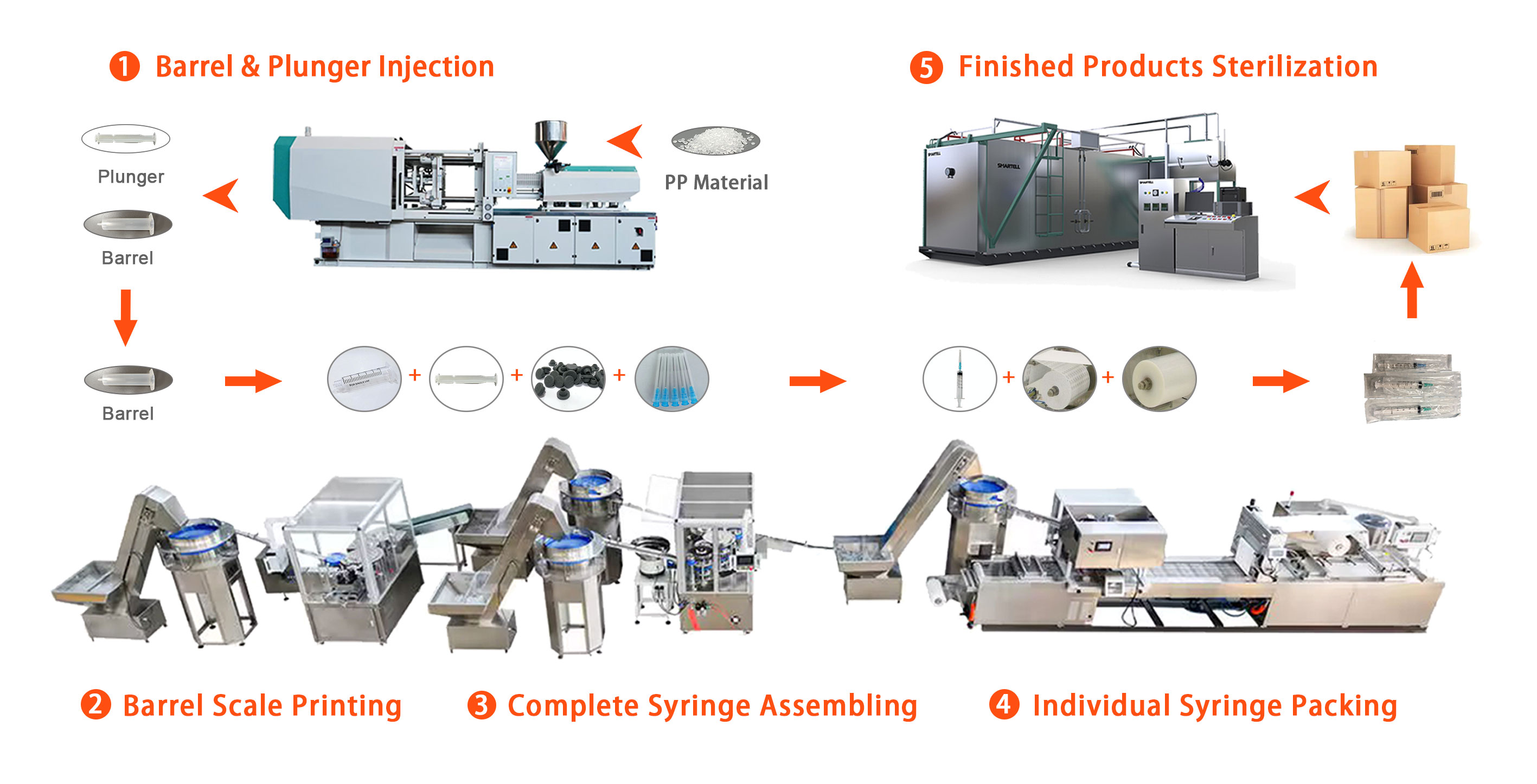

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.