| Availability: | |

|---|---|

| Quantity: | |

SMARTELL

The Syringe Production Line is a fully integrated solution for manufacturing disposable medical syringes.

It includes the complete process from raw material injection molding to final sterilized packaging.

This line ensures high efficiency, stable quality, and minimal human contact, meeting strict medical industry standards.

We provide a one-stop turnkey solution, covering equipment, molds, process technology, and raw materials.

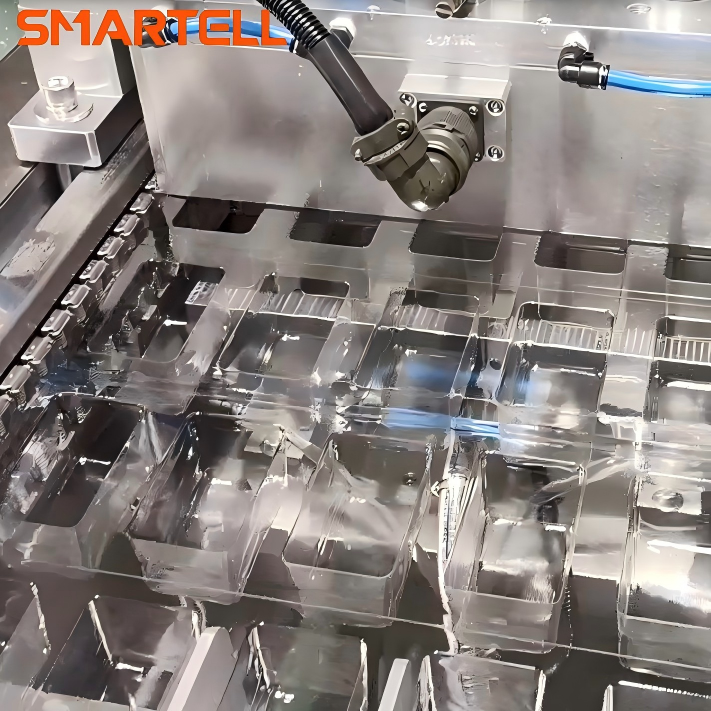

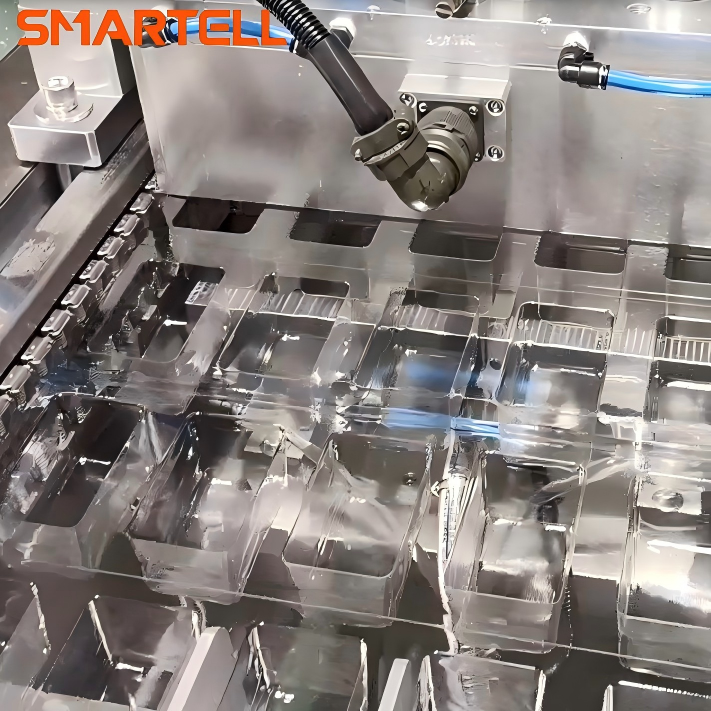

1.Injection Molding – Barrel & Plunger Manufacturing

Injection molding is the first step of syringe manufacturing.

High-precision molds and medical-grade PP material are used to produce barrels, plungers, and gaskets.

Barrel Mould

Barrel Mould

Plunger Mould

Gasket Mould

2. Syringe Printing – Graduation Marking

After molding, the barrel is transferred to the printing machine, where the graduation scale is printed.

3. Syringe Assembly – Barrel + Plunger + Gasket + Needle

4. Syringe Packing – Paper/Film Blister or PE Bag

Packaging can be done using a soft blister packing machine or automatic PE bag packing machine.

5. Sterilization – ETO

Advantages of the Complete Syringe Production Line

One-stop automated solution from molding to sterilization

High output, suitable for large-scale manufacturing

Minimal human contact, improved hygiene and quality

Stable and consistent product performance

Energy-efficient machines with low maintenance cost

Customizable for 1ml–60ml syringes, with or without needle

The Syringe Production Line is a fully integrated solution for manufacturing disposable medical syringes.

It includes the complete process from raw material injection molding to final sterilized packaging.

This line ensures high efficiency, stable quality, and minimal human contact, meeting strict medical industry standards.

We provide a one-stop turnkey solution, covering equipment, molds, process technology, and raw materials.

1.Injection Molding – Barrel & Plunger Manufacturing

Injection molding is the first step of syringe manufacturing.

High-precision molds and medical-grade PP material are used to produce barrels, plungers, and gaskets.

Barrel Mould

Barrel Mould

Plunger Mould

Gasket Mould

2. Syringe Printing – Graduation Marking

After molding, the barrel is transferred to the printing machine, where the graduation scale is printed.

3. Syringe Assembly – Barrel + Plunger + Gasket + Needle

4. Syringe Packing – Paper/Film Blister or PE Bag

Packaging can be done using a soft blister packing machine or automatic PE bag packing machine.

5. Sterilization – ETO

Advantages of the Complete Syringe Production Line

One-stop automated solution from molding to sterilization

High output, suitable for large-scale manufacturing

Minimal human contact, improved hygiene and quality

Stable and consistent product performance

Energy-efficient machines with low maintenance cost

Customizable for 1ml–60ml syringes, with or without needle