| Availability: | |

|---|---|

| Quantity: | |

SMT-4420

Smartell

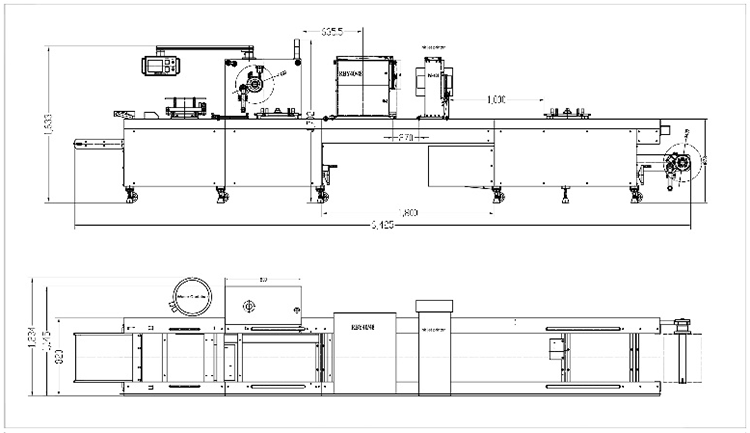

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Looking ahead, several advancements are shaping the future of syringe blister packing machines:

1. Increased Automation and AI Integration: More advanced machines are being developed with artificial intelligence (AI) and machine learning capabilities to enhance speed, efficiency, and error detection. These technologies help optimize the packaging process, reduce waste, and improve overall system reliability.

2. Sustainability: With growing concerns about environmental impact, there is a shift toward eco-friendly materials in syringe blister packaging. Manufacturers are exploring sustainable alternatives to plastic and foil, as well as recyclable or biodegradable materials that maintain sterility while reducing environmental impact.

3. Smart Packaging: The integration of RFID tags and QR codes in blister packs enables better traceability, product verification, and enhanced patient safety. Smart packaging also provides valuable data for manufacturers and healthcare providers, improving inventory management and product tracking.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

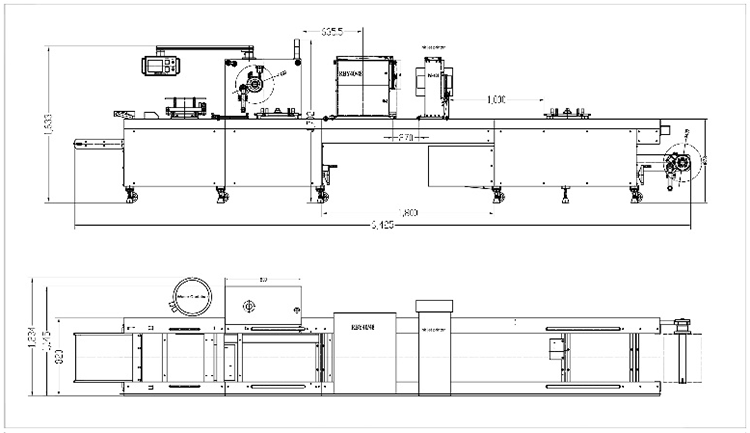

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Looking ahead, several advancements are shaping the future of syringe blister packing machines:

1. Increased Automation and AI Integration: More advanced machines are being developed with artificial intelligence (AI) and machine learning capabilities to enhance speed, efficiency, and error detection. These technologies help optimize the packaging process, reduce waste, and improve overall system reliability.

2. Sustainability: With growing concerns about environmental impact, there is a shift toward eco-friendly materials in syringe blister packaging. Manufacturers are exploring sustainable alternatives to plastic and foil, as well as recyclable or biodegradable materials that maintain sterility while reducing environmental impact.

3. Smart Packaging: The integration of RFID tags and QR codes in blister packs enables better traceability, product verification, and enhanced patient safety. Smart packaging also provides valuable data for manufacturers and healthcare providers, improving inventory management and product tracking.

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

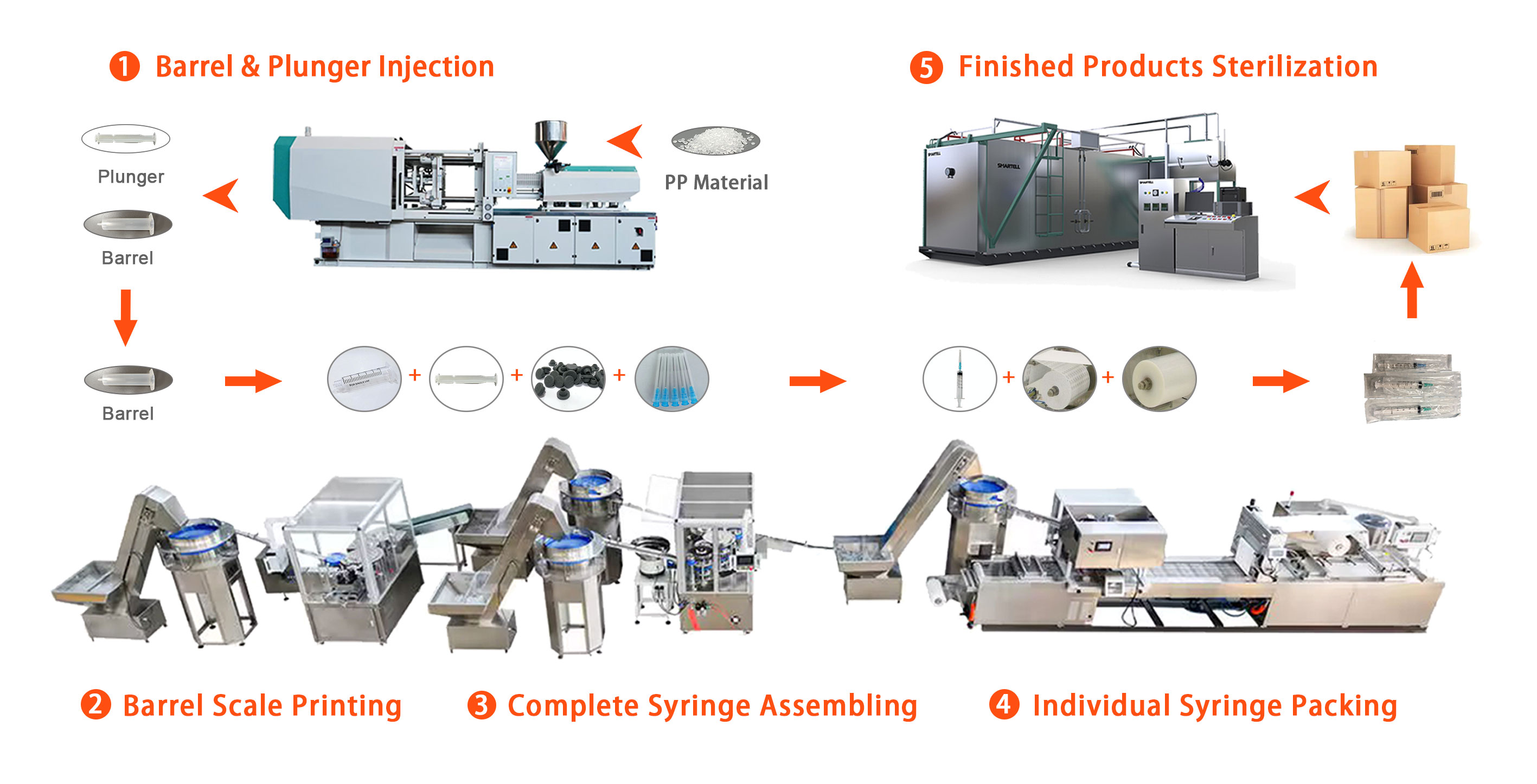

Automatic Medical Use Syringe Blister Packing Machine

The syringe blister packing machine is a vital component of modern medical manufacturing, ensuring that injectable medications are packaged securely, efficiently, and in compliance with regulatory standards. With the rise of personalized medicine and biologics, the demand for high-quality syringe blister packing lines will only continue to grow. We will need to adapt to new technological advancements, including automation, sustainability, and smart packaging, to meet the evolving needs of the industry and ensure patient safety and satisfaction.

As injectable drugs continue to form an integral part of treatment options, the importance of reliable, efficient, and sterile syringe packaging systems will only increase, making syringe blister packing machines a cornerstone of the medical packaging industry.

Automatic Medical Use Syringe Blister Packing Machine

The syringe blister packing machine is a vital component of modern medical manufacturing, ensuring that injectable medications are packaged securely, efficiently, and in compliance with regulatory standards. With the rise of personalized medicine and biologics, the demand for high-quality syringe blister packing lines will only continue to grow. We will need to adapt to new technological advancements, including automation, sustainability, and smart packaging, to meet the evolving needs of the industry and ensure patient safety and satisfaction.

As injectable drugs continue to form an integral part of treatment options, the importance of reliable, efficient, and sterile syringe packaging systems will only increase, making syringe blister packing machines a cornerstone of the medical packaging industry.

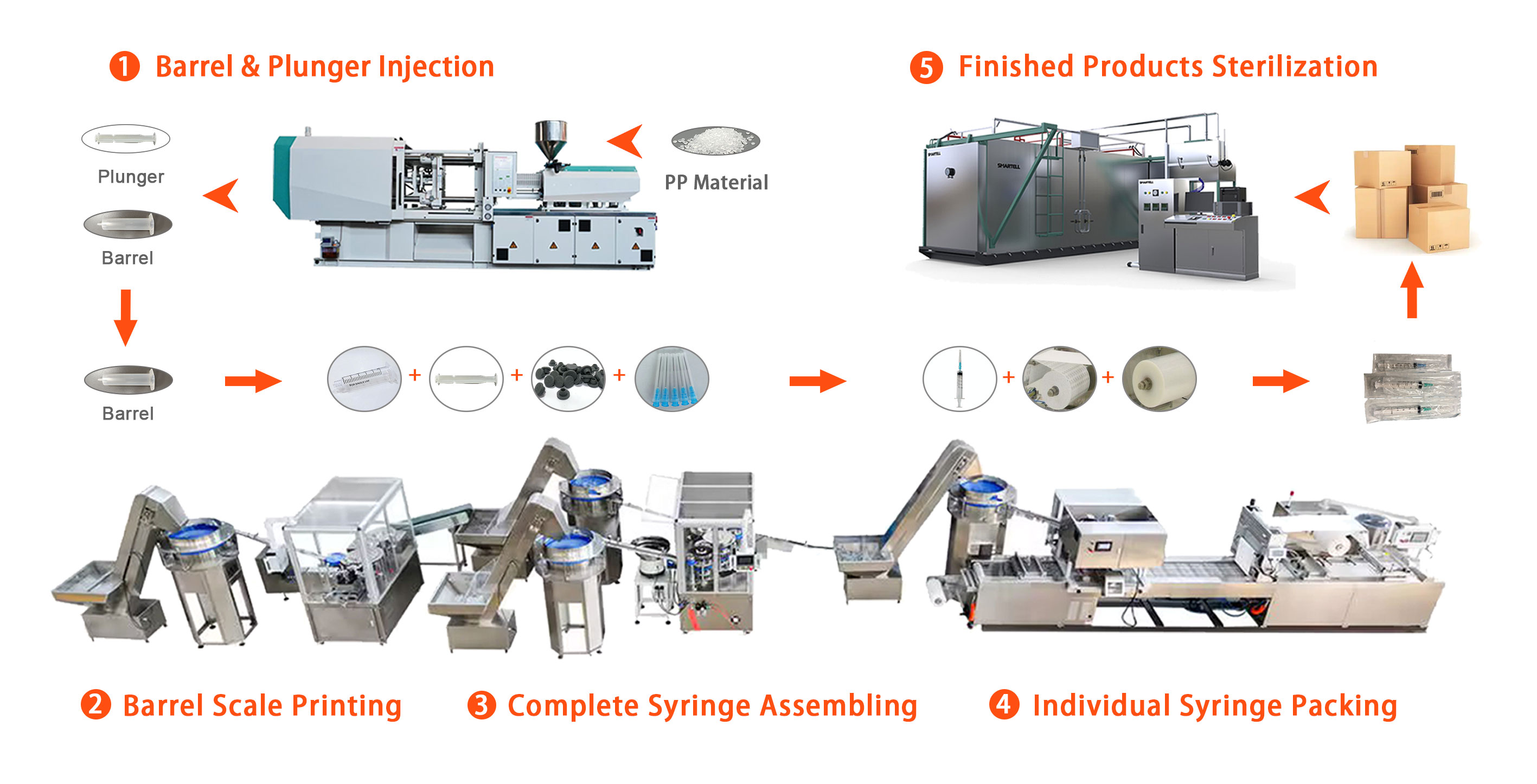

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.