| Availability: | |

|---|---|

| Quantity: | |

SMT-1111

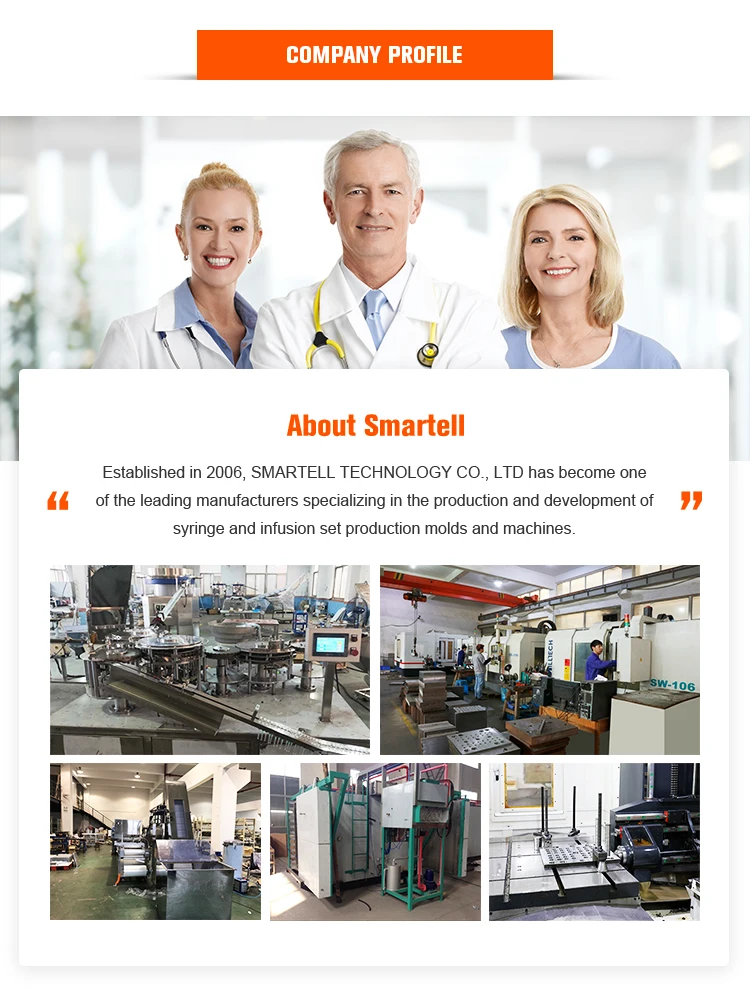

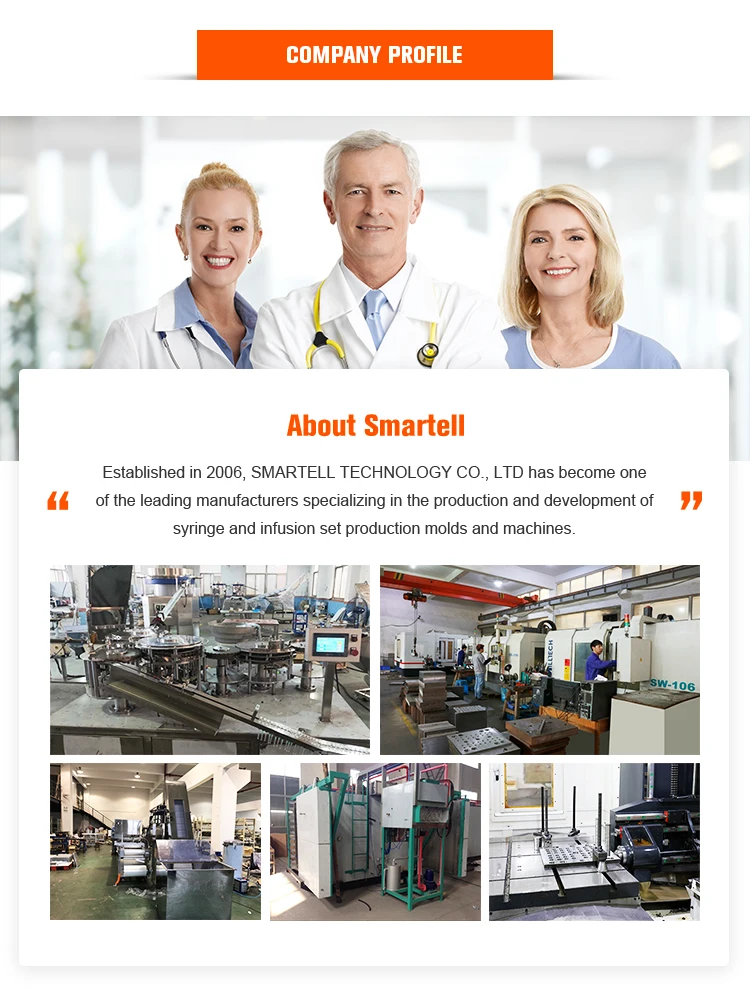

Smartell

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

Once the PVC is melted and mixed, it is forced through the Double-tubing Extrusion Mold, where it takes shape. The mold plays a pivotal role in determining the final shape, thickness, and consistency of the tubes. This mold is designed with a dual-runner, dual-cavity structure, allowing the machine to produce two PVC tubes simultaneously in one pass. This feature significantly increases the production capacity and operational efficiency.

3D Optimized Design: The Double-tubing Extrusion Mold is designed with advanced 3D optimization techniques to ensure optimal flow distribution and reduce potential material waste. This ensures that both tubes produced in each cycle maintain consistent dimensions, improving both production efficiency and product quality.

Precise Tube Shaping: The design of the mold ensures that the inner and outer diameters of the tube remain uniform throughout the production process, which is essential for maintaining the safety and effectiveness of medical applications.

Once the PVC is melted and mixed, it is forced through the Double-tubing Extrusion Mold, where it takes shape. The mold plays a pivotal role in determining the final shape, thickness, and consistency of the tubes. This mold is designed with a dual-runner, dual-cavity structure, allowing the machine to produce two PVC tubes simultaneously in one pass. This feature significantly increases the production capacity and operational efficiency.

3D Optimized Design: The Double-tubing Extrusion Mold is designed with advanced 3D optimization techniques to ensure optimal flow distribution and reduce potential material waste. This ensures that both tubes produced in each cycle maintain consistent dimensions, improving both production efficiency and product quality.

Precise Tube Shaping: The design of the mold ensures that the inner and outer diameters of the tube remain uniform throughout the production process, which is essential for maintaining the safety and effectiveness of medical applications.

FAQ

FAQ