| Availability: | |

|---|---|

| Quantity: | |

SMT-1111

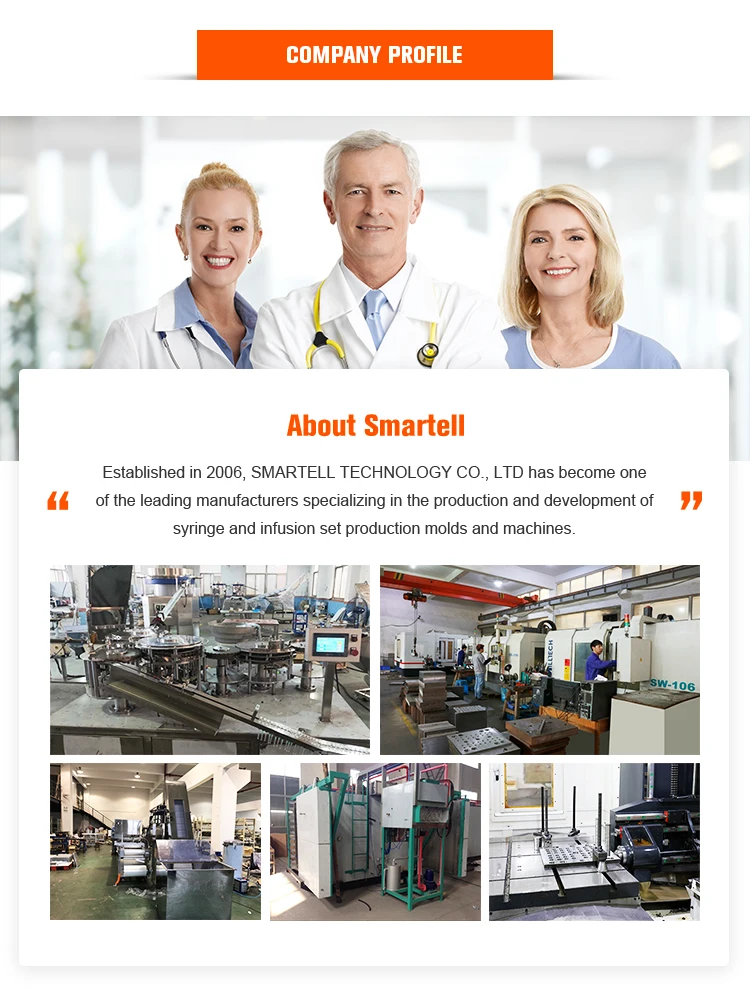

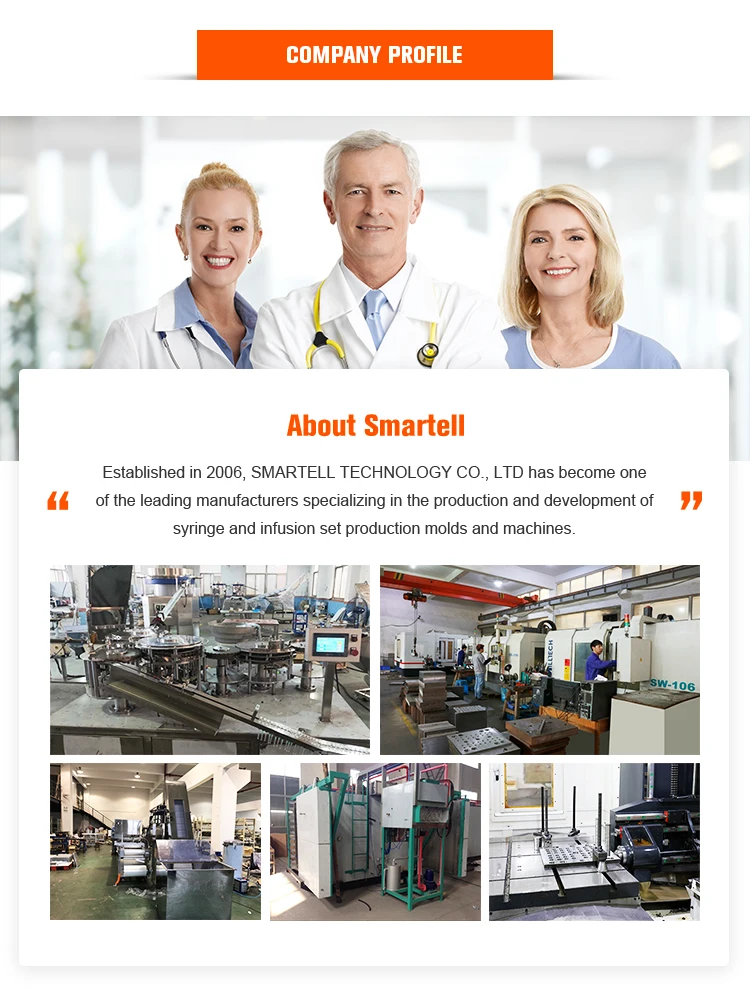

Smartell

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

In the rapidly growing medical device industry, precision and efficiency are vital, particularly when it comes to the manufacturing of medical-grade PVC tubes. These tubes, commonly used in infusion sets, catheters, and other medical equipment, require strict adherence to quality standards, while also needing to be produced in high volumes to meet global demand. To achieve these demanding requirements, manufacturers rely on advanced machinery, such as the Infusion Set PVC Tube Extruding Machine.

PVC tube extrusion is a process in which raw Polyvinyl Chloride (PVC) material is melted and forced through a mold to form continuous tube shapes. The Infusion Set PVC Tube Extruding Machine uses this technique to create high-quality medical tubes that are used in a wide range of applications, from drug administration via IV infusion to diagnostic instruments.

The High-Speed PVC Tube Extruding Machine stands out by producing 5000-6000 tubes per hour, making it a highly efficient choice for manufacturers looking to scale production without compromising on quality.

In the rapidly growing medical device industry, precision and efficiency are vital, particularly when it comes to the manufacturing of medical-grade PVC tubes. These tubes, commonly used in infusion sets, catheters, and other medical equipment, require strict adherence to quality standards, while also needing to be produced in high volumes to meet global demand. To achieve these demanding requirements, manufacturers rely on advanced machinery, such as the Infusion Set PVC Tube Extruding Machine.

PVC tube extrusion is a process in which raw Polyvinyl Chloride (PVC) material is melted and forced through a mold to form continuous tube shapes. The Infusion Set PVC Tube Extruding Machine uses this technique to create high-quality medical tubes that are used in a wide range of applications, from drug administration via IV infusion to diagnostic instruments.

The High-Speed PVC Tube Extruding Machine stands out by producing 5000-6000 tubes per hour, making it a highly efficient choice for manufacturers looking to scale production without compromising on quality.

FAQ

FAQ