| Availability: | |

|---|---|

| Quantity: | |

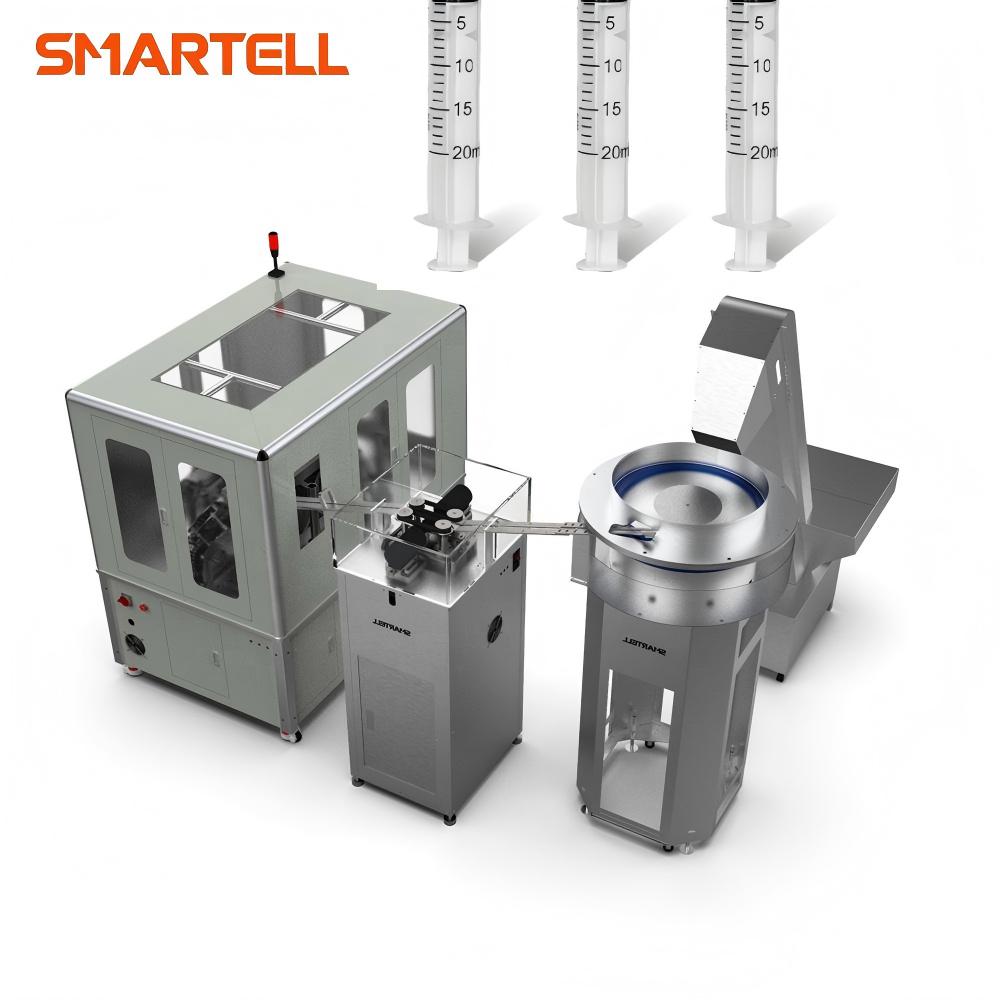

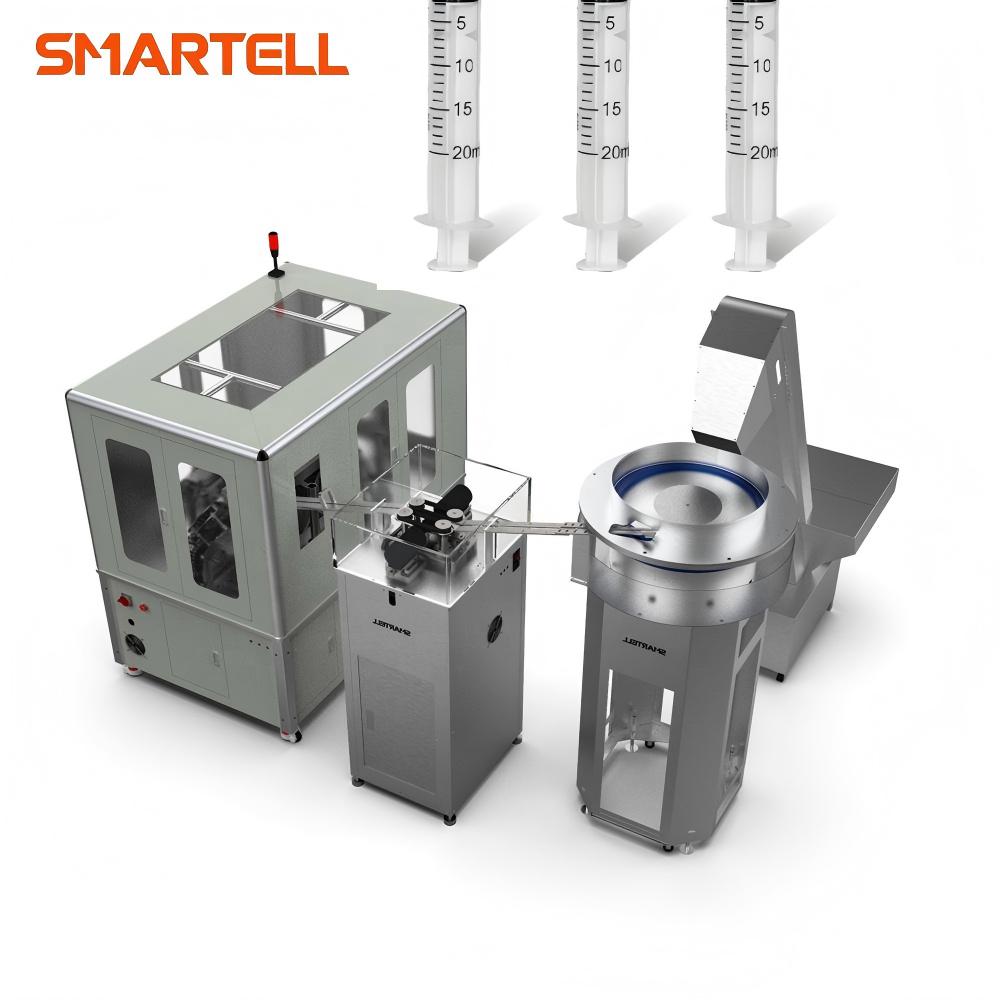

SMT-4420

SMARTELL

We offer a complete syringe production line, encompassing core equipment such as syringe molds, injection molding machines, barrel printing machines, assembly machines, packing machines, and sterilizers.

A key advantage of our solution lies in the high automation level of most machines. By minimizing manual intervention and reducing human contact throughout the production process, we not only significantly cut down on labor costs but also effectively avoid potential contamination risks. This automated approach directly contributes to maintaining stable, high-quality standards for the final syringe products.

Syringe components are precision-molded via injection molding machines equipped with specialized molds, using hot-melt polypropylene (PP) material. This stage is critical, as mold design precision directly dictates the dimensional accuracy and overall quality of the final syringe.

After injection,the syringe barrel and plunger is done.And the barrel need to print the scale lin on it .The pad printing machine is used to print clear and precise scale lines, drug names, dosage indicators, expiration dates and other information on the surface of syringe needles. These markings are the core basis for medical staff to accurately determine the dosage of medication and distinguish the types of drugs, and directly relate to the safety of patients' medication.

To guarantee sterility and eliminate microbial contamination, packaged syringes undergo ethylene oxide (ETO) gas sterilization before entering the market. The primary equipment here is an ETO sterilizer. For clients requiring faster processing, an optional preheating system can be added to reduce sterilization cycle time.

Barrel Mould

Injection Molding Machine

Printing Machine

Assembly Machine

Blister Packing Machine

Sterilization Machine

We offer a complete syringe production line, encompassing core equipment such as syringe molds, injection molding machines, barrel printing machines, assembly machines, packing machines, and sterilizers.

A key advantage of our solution lies in the high automation level of most machines. By minimizing manual intervention and reducing human contact throughout the production process, we not only significantly cut down on labor costs but also effectively avoid potential contamination risks. This automated approach directly contributes to maintaining stable, high-quality standards for the final syringe products.

Syringe components are precision-molded via injection molding machines equipped with specialized molds, using hot-melt polypropylene (PP) material. This stage is critical, as mold design precision directly dictates the dimensional accuracy and overall quality of the final syringe.

After injection,the syringe barrel and plunger is done.And the barrel need to print the scale lin on it .The pad printing machine is used to print clear and precise scale lines, drug names, dosage indicators, expiration dates and other information on the surface of syringe needles. These markings are the core basis for medical staff to accurately determine the dosage of medication and distinguish the types of drugs, and directly relate to the safety of patients' medication.

To guarantee sterility and eliminate microbial contamination, packaged syringes undergo ethylene oxide (ETO) gas sterilization before entering the market. The primary equipment here is an ETO sterilizer. For clients requiring faster processing, an optional preheating system can be added to reduce sterilization cycle time.

Barrel Mould

Injection Molding Machine

Printing Machine

Assembly Machine

Blister Packing Machine

Sterilization Machine