| Availability: | |

|---|---|

| Quantity: | |

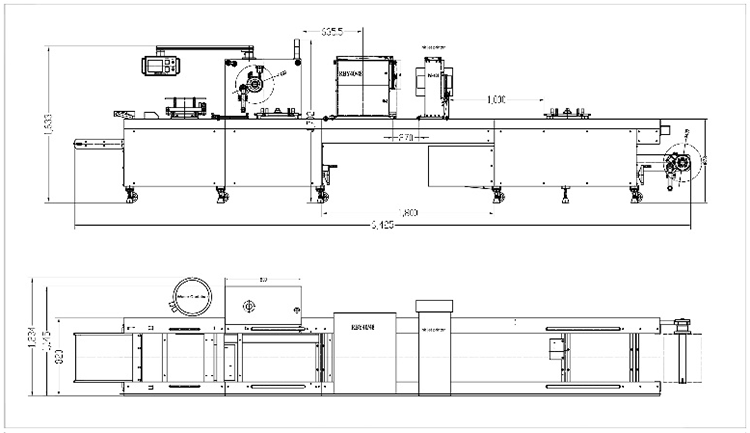

SMT-4420

Smartell

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

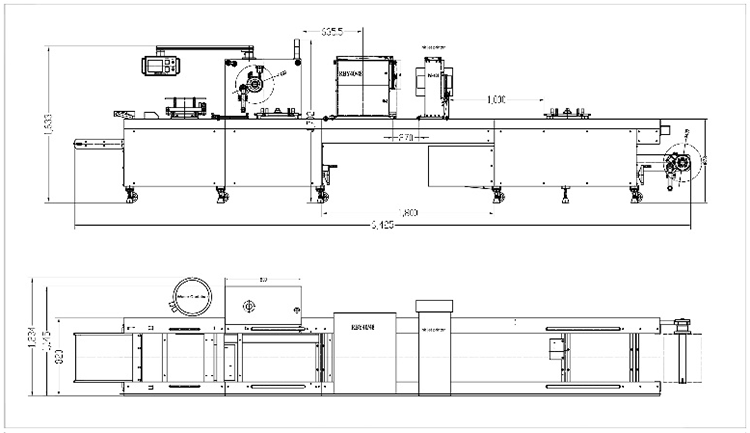

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

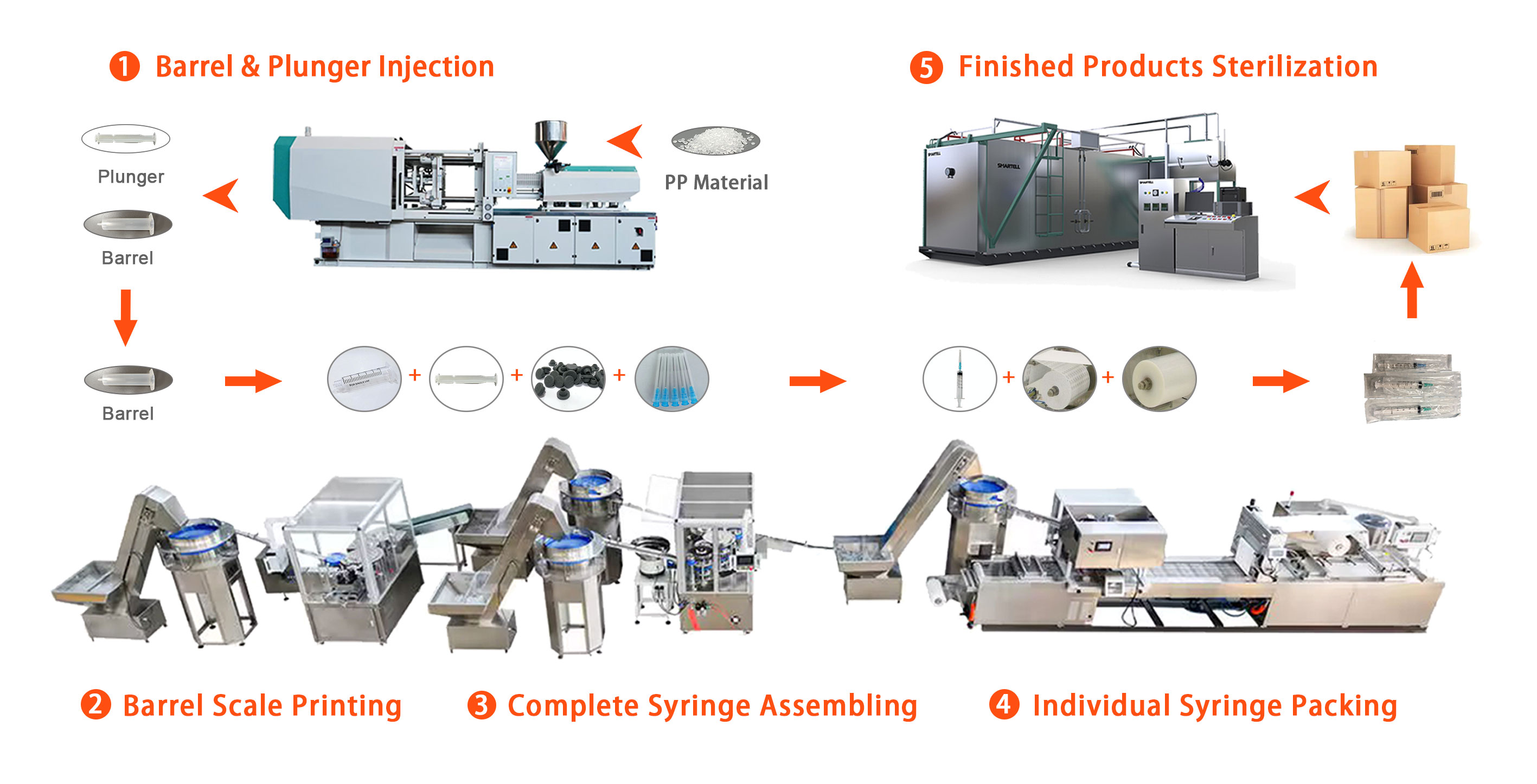

One of the most significant features of the Automatic Syringe PVC Blister Packing Machine is its high-speed performance. These machines are designed to work at very fast production rates, making them ideal for manufacturers that need to produce large quantities of packaged syringes in a short period of time. The SMT-4420 Syringe Soft Blister Packing Machine, for example, can process large numbers of syringes per minute, significantly boosting production efficiency while maintaining quality standards.

The cost-effectiveness of these machines comes from their ability to automate much of the packaging process, reducing the need for manual labor and minimizing the likelihood of human error. Manual packing is often slow, error-prone, and inconsistent, which can lead to wasted materials and higher operational costs. The SMT-4420 and similar machines, however, can work continuously and with minimal oversight, reducing production costs and increasing profitability.

Moreover, these machines are designed to adapt to different production needs, which means that even though they are cost-effective, they do not sacrifice versatility. The ability to package syringes with different configurations, such as syringes with attached needles or syringes in varying sizes, makes them indispensable in a medical production line.

One of the most significant features of the Automatic Syringe PVC Blister Packing Machine is its high-speed performance. These machines are designed to work at very fast production rates, making them ideal for manufacturers that need to produce large quantities of packaged syringes in a short period of time. The SMT-4420 Syringe Soft Blister Packing Machine, for example, can process large numbers of syringes per minute, significantly boosting production efficiency while maintaining quality standards.

The cost-effectiveness of these machines comes from their ability to automate much of the packaging process, reducing the need for manual labor and minimizing the likelihood of human error. Manual packing is often slow, error-prone, and inconsistent, which can lead to wasted materials and higher operational costs. The SMT-4420 and similar machines, however, can work continuously and with minimal oversight, reducing production costs and increasing profitability.

Moreover, these machines are designed to adapt to different production needs, which means that even though they are cost-effective, they do not sacrifice versatility. The ability to package syringes with different configurations, such as syringes with attached needles or syringes in varying sizes, makes them indispensable in a medical production line.

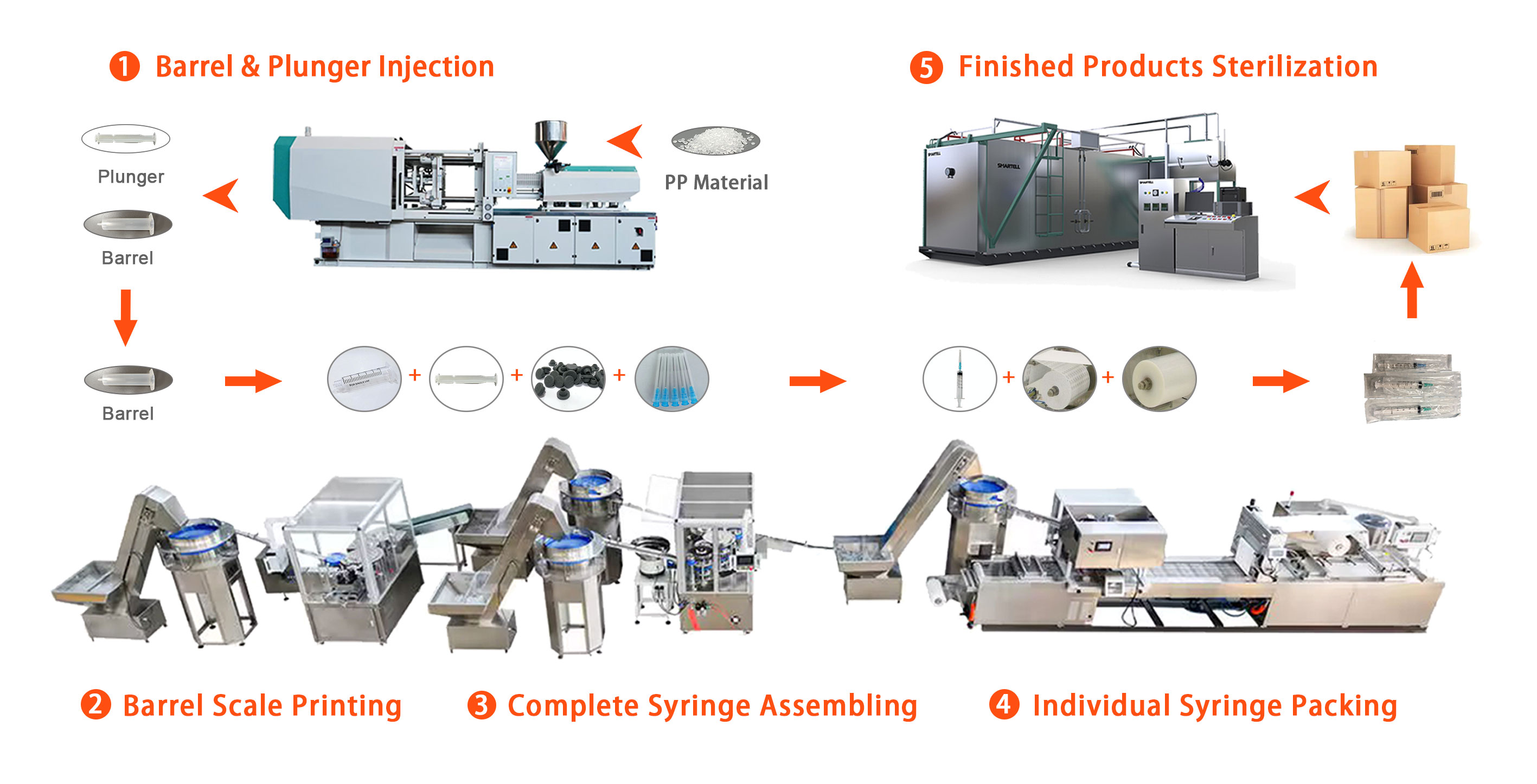

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.