| Availability: | |

|---|---|

| Quantity: | |

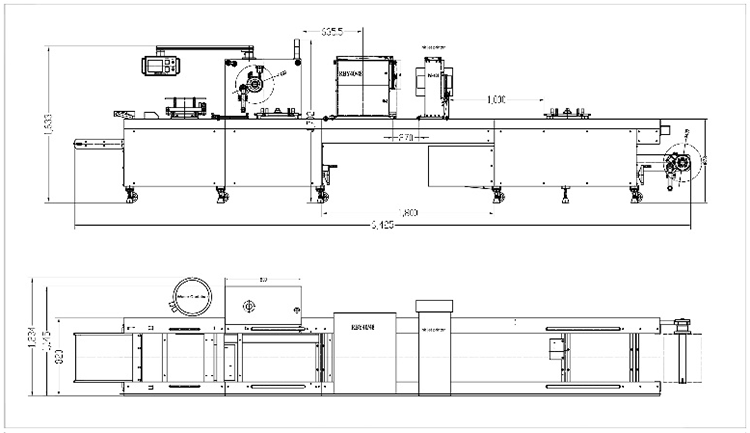

SMT-4420

Smartell

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

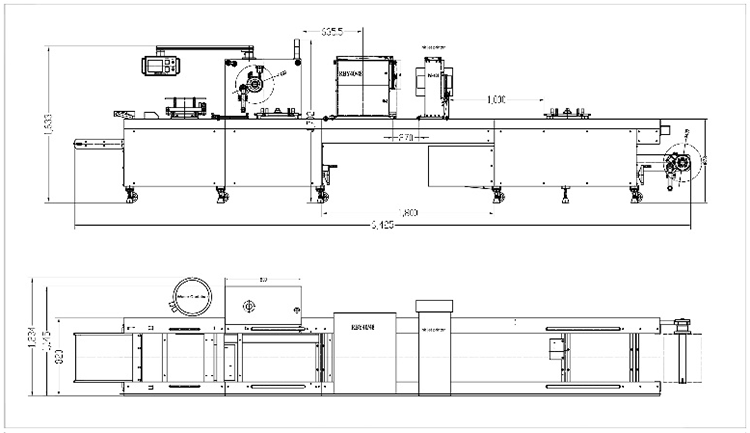

Soft Blister Packing Machine

Cutting Section

Paper Load

Film Load

Waste Paper Container

Blister Packing Mold

Maximum Packing Width | 300mm,400mm,460mm,480mm,540mm | ||

Minimum Packing Width | 19mm | Maximum Packing Length | 60mm |

Working Cycle | 4-6s | Voltage | 3x380V+N+E/50HZ |

Air Pressure | 0.6-0.8Mpa | Air Consumption | 700NL/MIN |

Power | 10kw | Cooling Water | 80L/h(<25°) |

The material used for the blister packs is equally important. Soft blister paper film is an essential component of these packing machines, as it provides a protective seal around medical devices like syringes. The excellent paper/film structure used in these machines is durable enough to withstand handling but soft enough to ensure the product is not damaged during the packing process. This material is also non-reactive, ensuring that no harmful chemical reactions occur between the blister pack and the contents inside.

Moreover, soft blister paper film can be made from a variety of materials, including PVC, PET, or aluminum, depending on the requirements for barrier protection. The film's flexibility allows it to mold around syringes with precision, providing a snug and secure fit, which is critical for preventing contamination.

For many medical devices, individual packing is essential to maintaining product integrity. Some products, like syringes with attached needles, require extra care in terms of packaging. This is where the Needs Individual Packing Medical Product Option for Auto Loader Soft Blister Packing Machine becomes highly beneficial. This feature allows each syringe or medical device to be individually loaded and packaged without the need for manual intervention, streamlining the process and reducing errors.

The individual packing option is particularly important in maintaining the sterility of each syringe or device. By isolating each item in its own sealed blister pack, manufacturers can ensure that contamination does not occur between different products, which is a major concern in medical production environments.

The material used for the blister packs is equally important. Soft blister paper film is an essential component of these packing machines, as it provides a protective seal around medical devices like syringes. The excellent paper/film structure used in these machines is durable enough to withstand handling but soft enough to ensure the product is not damaged during the packing process. This material is also non-reactive, ensuring that no harmful chemical reactions occur between the blister pack and the contents inside.

Moreover, soft blister paper film can be made from a variety of materials, including PVC, PET, or aluminum, depending on the requirements for barrier protection. The film's flexibility allows it to mold around syringes with precision, providing a snug and secure fit, which is critical for preventing contamination.

For many medical devices, individual packing is essential to maintaining product integrity. Some products, like syringes with attached needles, require extra care in terms of packaging. This is where the Needs Individual Packing Medical Product Option for Auto Loader Soft Blister Packing Machine becomes highly beneficial. This feature allows each syringe or medical device to be individually loaded and packaged without the need for manual intervention, streamlining the process and reducing errors.

The individual packing option is particularly important in maintaining the sterility of each syringe or device. By isolating each item in its own sealed blister pack, manufacturers can ensure that contamination does not occur between different products, which is a major concern in medical production environments.

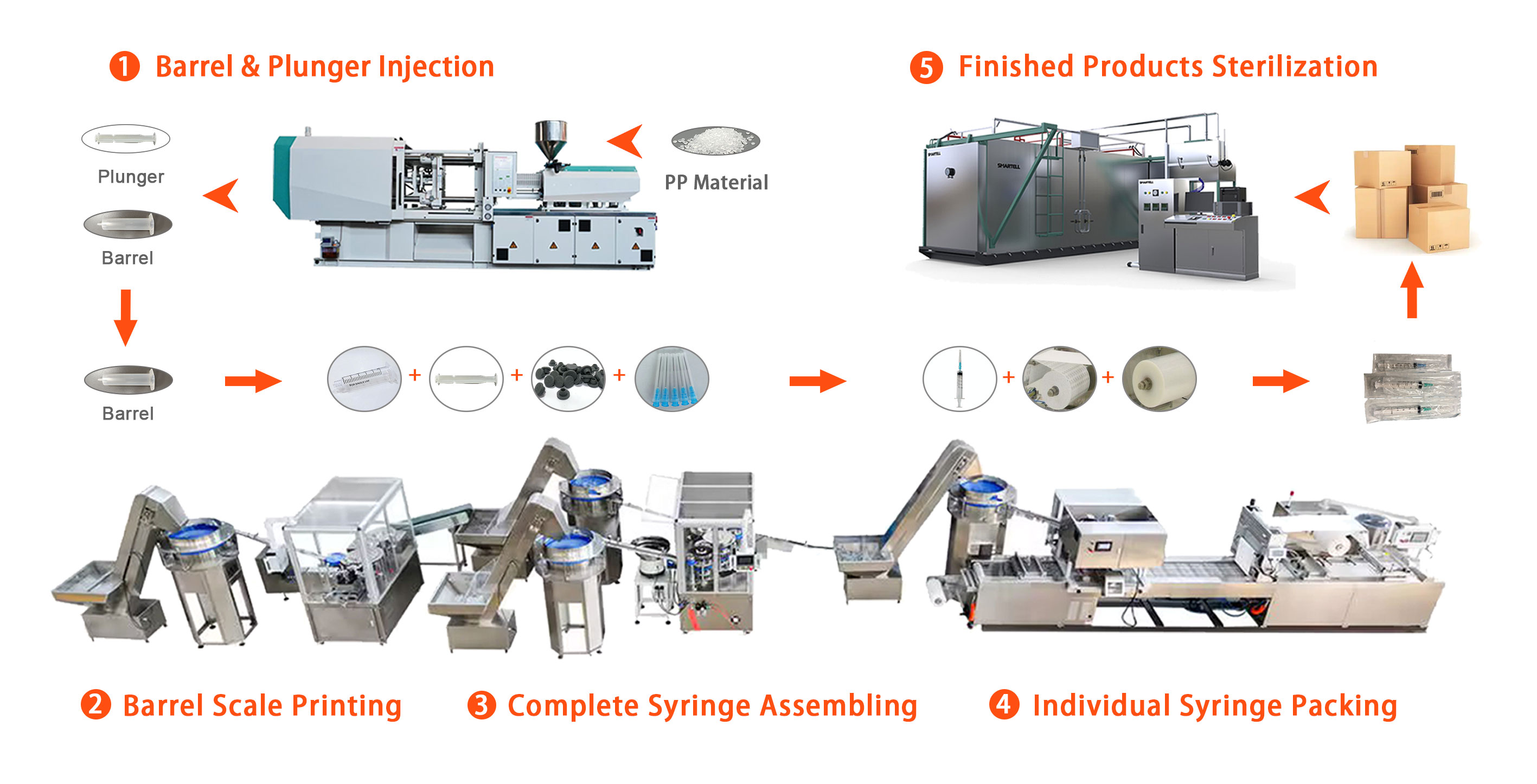

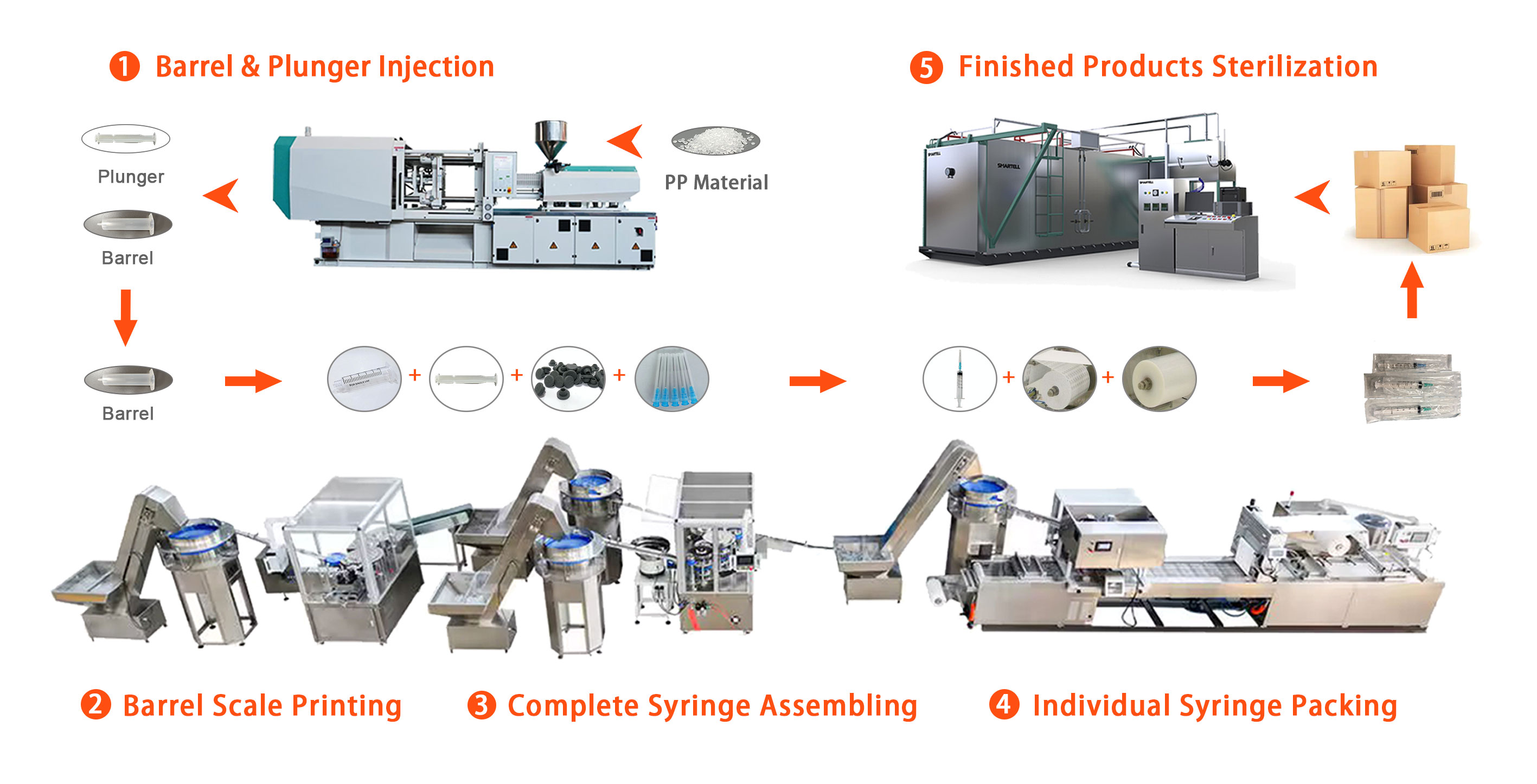

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.

SMARTELL TECHNOLOGY CO. LTD has become one of the leading companies specializing in the production and development of syringes and infusion set production projects.

Our products and services are as follows based on our over 18 years of experience:

1.Molds&machines for several syringe-type: disposable syringe, AD syringe, insulin syringe, oral feed syringes, etc.

2. Molds and machines for infusion set parts.

3. Raw material and spare parts supply for the syringe project.

4. Online technical support: project relevant questions and answers such as material consumption analysis, labor requirement suggestion, electrical power consumption, etc.

5.Workshop layout, field installation,and operator training.

6. One-year warranty and lifetime maintenance.

We have cooperated with over 108 clients from many countries such as Egypt, Turkey, India, Indonesia, Uzbekistan, Iraq, Chile, Bulgaria,Korea, Vietnam, Philippines, Russia, etc.

We also have developed sub-offices in India, Indonesia, Egypt, and Turkey to offer local machine installation and maintenance to lessen the total cost from the clients and improve communication effect between the engineers and clients in these countries.