| Availability: | |

|---|---|

| Quantity: | |

SMT-1111

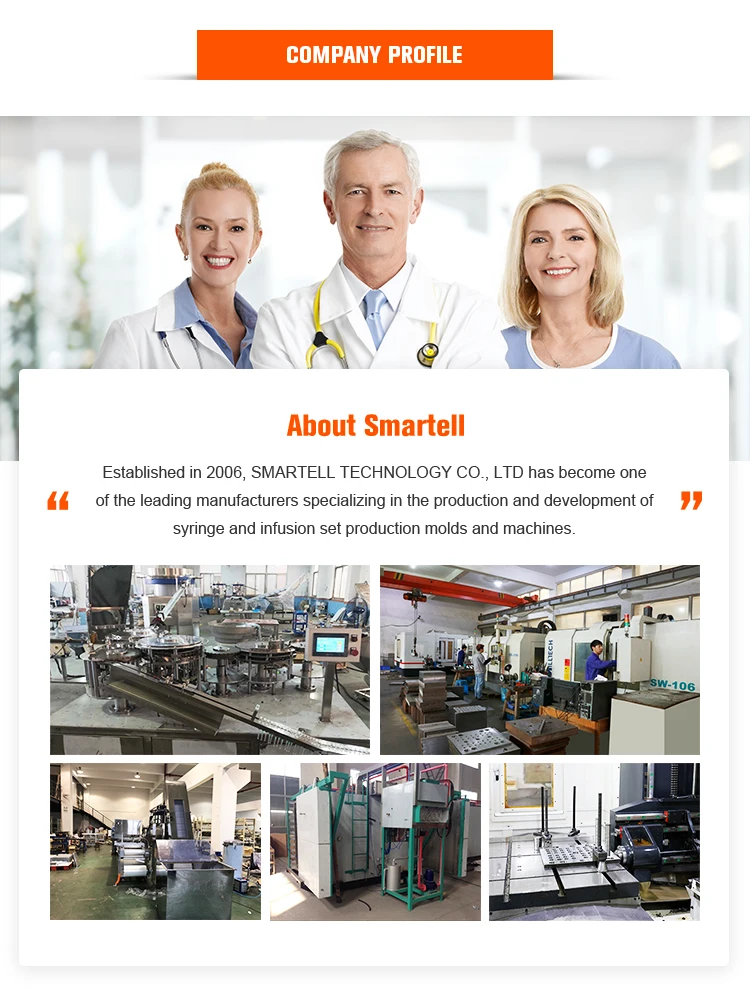

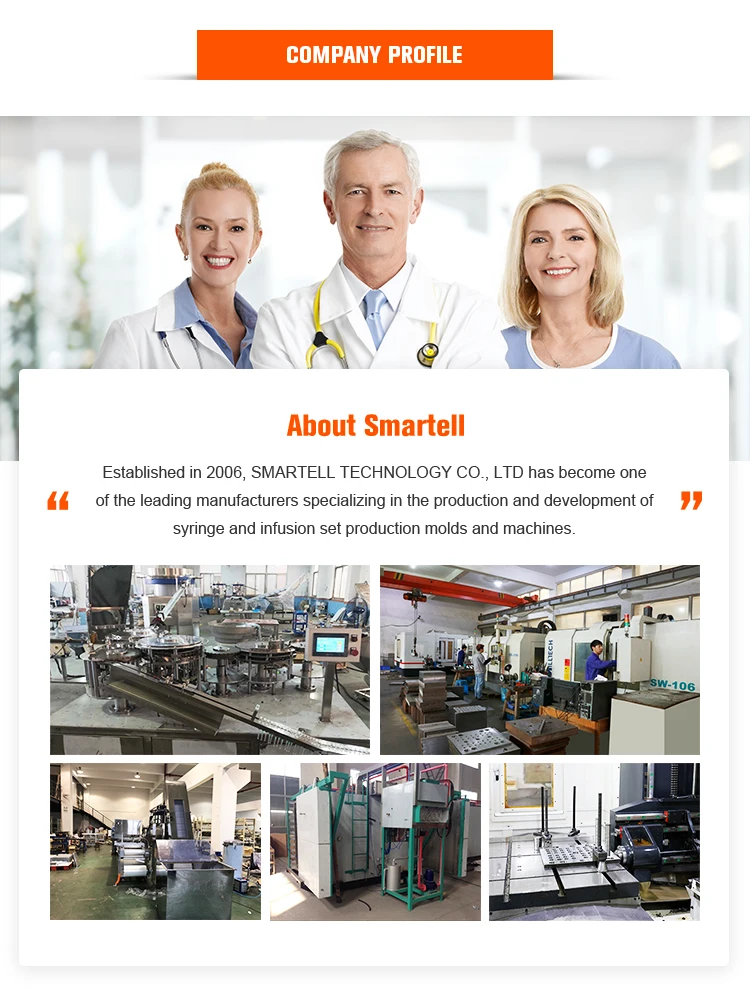

Smartell

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

With all of these advanced features, the High-Speed PVC Tube Extruding Machine provides significant benefits to manufacturers in the medical device industry:

1. High Production Capacity: The ability to produce 5000-6000 tubes per hour allows manufacturers to meet large-scale demands, whether for hospital use, pharmaceutical applications, or medical product manufacturers.

2. Precision and Consistency: From the Single Screw Extruder to the Microcomputer Tube Cutting Machine, the entire system is designed to ensure the production of tubes with consistent dimensions, uniform thickness, and high-quality finishes.

3. Reduced Downtime and Maintenance Costs: The machine is built for reliability, with high-quality components that reduce the likelihood of mechanical failures. Additionally, the Self-circulating Water Chiller and automated controls decrease the need for frequent manual intervention.

4. Improved Efficiency: Features like the Double-tubing Extrusion Mold and Dual-track Traction Machine significantly reduce production time while improving throughput. This results in lower operational costs and faster production cycles.

5. Enhanced Flexibility: The PLC-controlled system allows for easy adjustments and fine-tuning of parameters, providing manufacturers with flexibility in terms of tube specifications, production speed, and cutting lengths.

With all of these advanced features, the High-Speed PVC Tube Extruding Machine provides significant benefits to manufacturers in the medical device industry:

1. High Production Capacity: The ability to produce 5000-6000 tubes per hour allows manufacturers to meet large-scale demands, whether for hospital use, pharmaceutical applications, or medical product manufacturers.

2. Precision and Consistency: From the Single Screw Extruder to the Microcomputer Tube Cutting Machine, the entire system is designed to ensure the production of tubes with consistent dimensions, uniform thickness, and high-quality finishes.

3. Reduced Downtime and Maintenance Costs: The machine is built for reliability, with high-quality components that reduce the likelihood of mechanical failures. Additionally, the Self-circulating Water Chiller and automated controls decrease the need for frequent manual intervention.

4. Improved Efficiency: Features like the Double-tubing Extrusion Mold and Dual-track Traction Machine significantly reduce production time while improving throughput. This results in lower operational costs and faster production cycles.

5. Enhanced Flexibility: The PLC-controlled system allows for easy adjustments and fine-tuning of parameters, providing manufacturers with flexibility in terms of tube specifications, production speed, and cutting lengths.

FAQ

FAQ