| Availability: | |

|---|---|

| Quantity: | |

SMT-1111

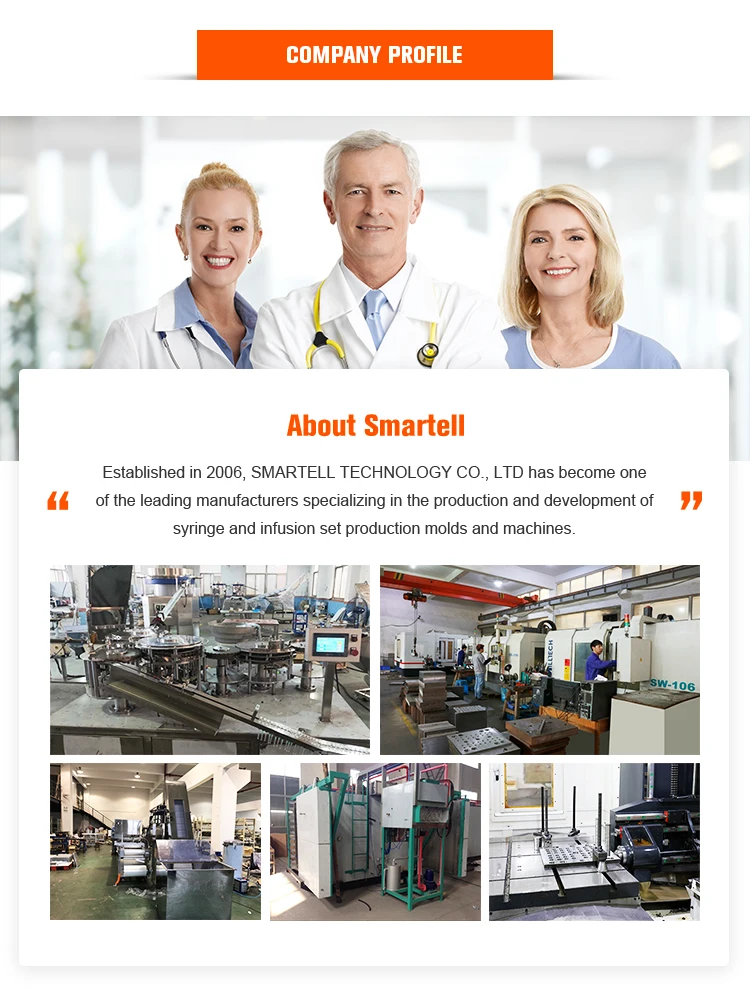

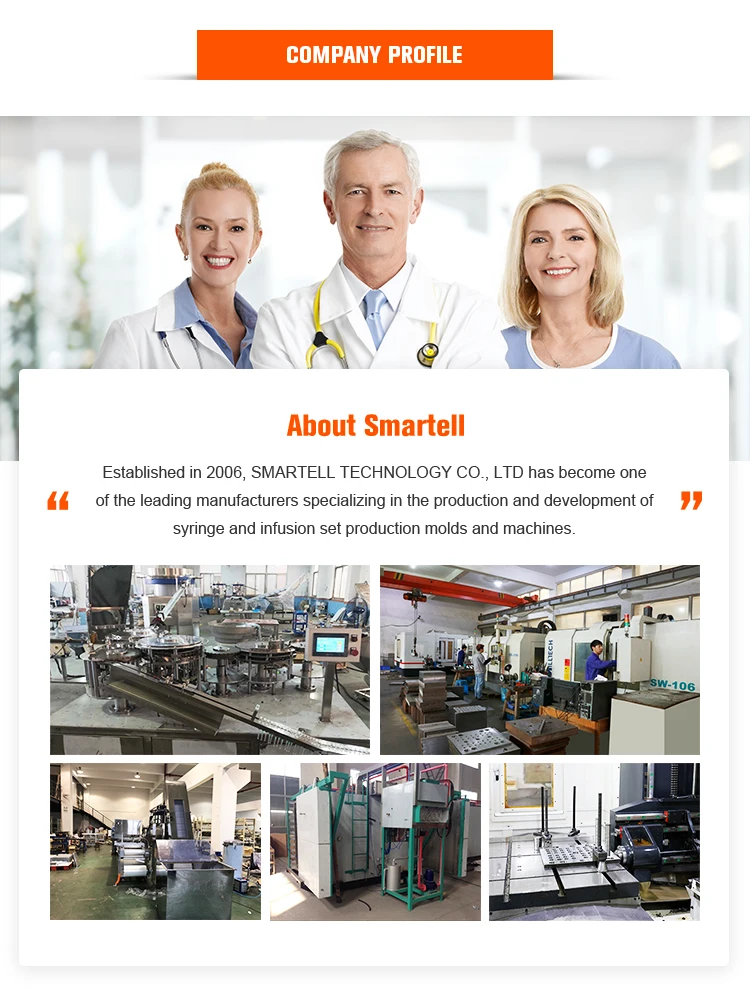

Smartell

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

Basic Parameter

Screw Diameter | 65mm |

Screw L/D Radio | 28:1 |

Machine Weight | 1200kg |

Dimension | 2850*680*1550mm |

Capacity | 60-80kg/h |

Voltage | 380V/50HZ |

Motor Power | 22kw |

Frequency Converter Power | 22kw |

All parameters and dimensions are subject to change without prior notice.

Cooling is a critical step in the extrusion process. After the melted PVC exits the mold, it needs to be cooled down quickly and evenly to solidify and retain its shape. The Double-layer Cooling Water Tank System provides efficient cooling for the extruded tubes.

Stainless Steel Construction: The cooling tank is made from high-quality stainless steel, ensuring durability and resistance to corrosion, especially considering the continuous flow of water and the contact with PVC material.

Double-Layer Design: The cooling system includes two layers of water flow, optimizing heat transfer efficiency. The first layer ensures rapid initial cooling, while the second layer stabilizes the temperature, providing the tubes with the right firmness and preventing warping.

Aluminium Alloy Self-Drying Device: This device is incorporated to speed up the drying process by removing excess water from the tubes. By reducing water retention, the tubes dry faster, which helps maintain their structural integrity and ensures they are ready for the next stages of production.

Cooling is a critical step in the extrusion process. After the melted PVC exits the mold, it needs to be cooled down quickly and evenly to solidify and retain its shape. The Double-layer Cooling Water Tank System provides efficient cooling for the extruded tubes.

Stainless Steel Construction: The cooling tank is made from high-quality stainless steel, ensuring durability and resistance to corrosion, especially considering the continuous flow of water and the contact with PVC material.

Double-Layer Design: The cooling system includes two layers of water flow, optimizing heat transfer efficiency. The first layer ensures rapid initial cooling, while the second layer stabilizes the temperature, providing the tubes with the right firmness and preventing warping.

Aluminium Alloy Self-Drying Device: This device is incorporated to speed up the drying process by removing excess water from the tubes. By reducing water retention, the tubes dry faster, which helps maintain their structural integrity and ensures they are ready for the next stages of production.

FAQ

FAQ